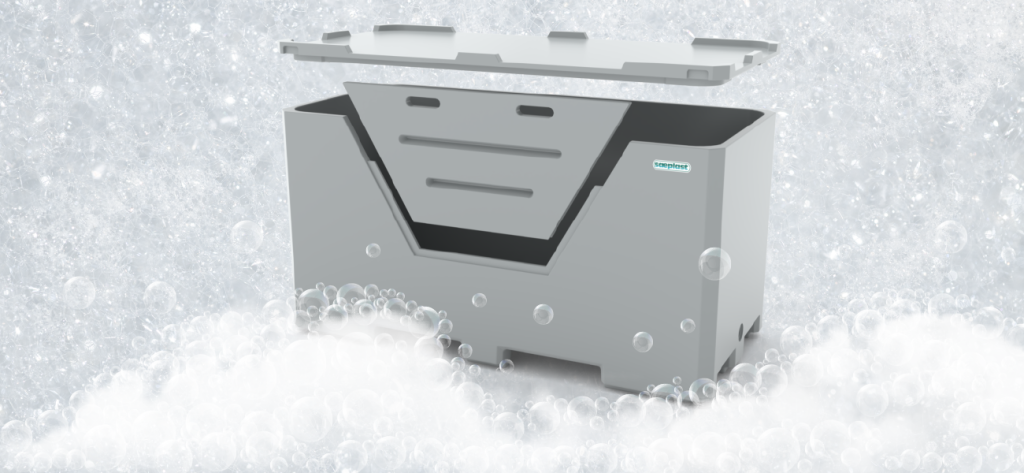

Uppgötvaðu Sæplast fyrir

Úrgangs- og endurvinnsluiðnaður

Uppgötvaðu Sæplast-ílát sem eru

Gerð til að leysa vandamálin þín

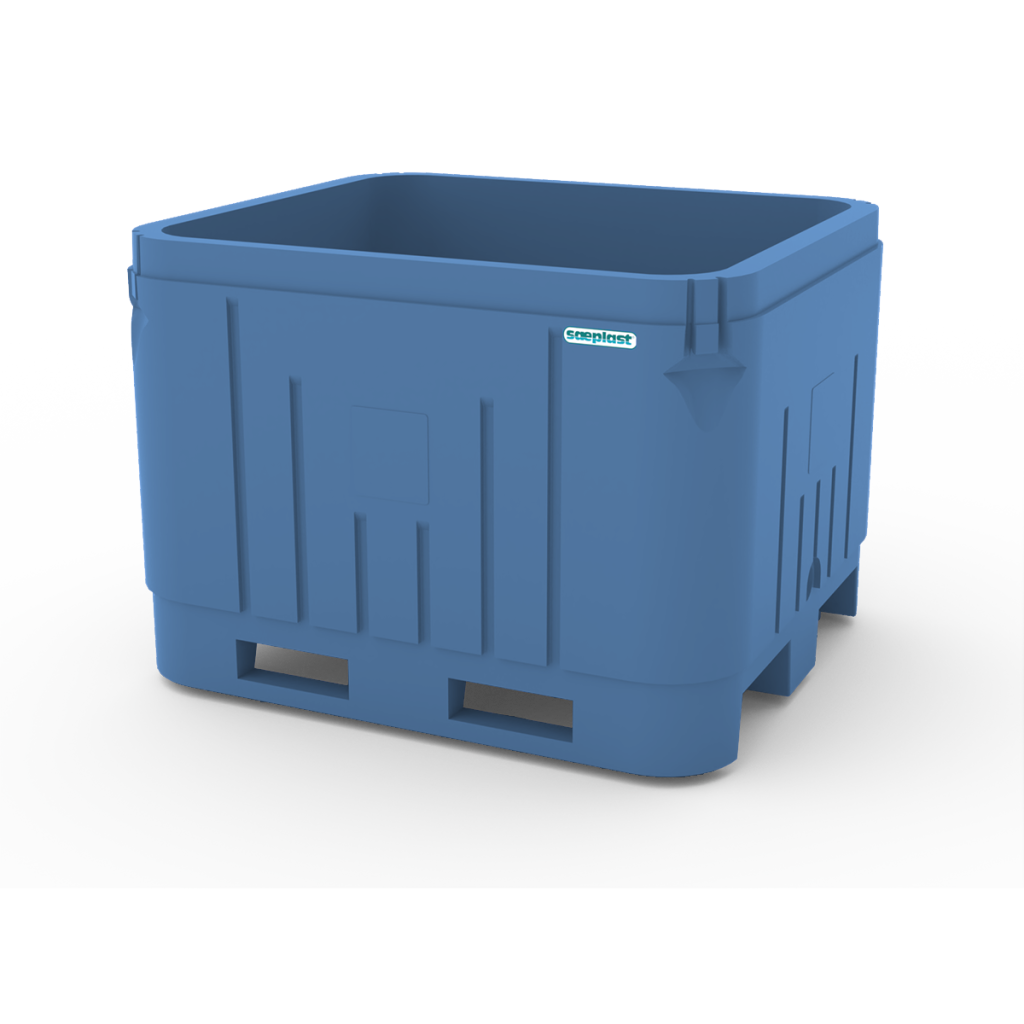

Sæplast styður úrgangs- og endurvinnsluiðnaðinn með endingargóðum og traustum lausnum sem hönnuð eru til að standa sig í krefjandi umhverfi með miklum áhrifum. Ílátin okkar einfalda söfnun, bæta meðhöndlun og þola mikla daglega notkun – sem dregur úr endurnýjunarkostnaði og niðurtíma. Frá iðnaðarúrgangi til efnisendurheimtar bjóðum við upp á áreiðanleika sem þú getur treyst.

Með því að innleiða endingargóða og sjálfbæra ruslagi Saeplast í starfsemi ykkar geta fyrirtæki:

Lækka kostnað með langvarandi, endurnýtanlegum lausnum

Bæta hreinlæti og lágmarka hættu á mengun

Lækkaðu flutnings- og vörustjórnunarkostnað með staflanlegum hönnunum

Styðjið sjálfbærni með fullkomlega endurvinnanlegu efni

Bættu rekstrarhagkvæmni með vinnuaðlögunarhæfum hönnunum sem henta gaffaltrukkum.

Verslaðu allt úrgangs- og endurvinnsluefni:

Af hverju nota Sæplast

í úrgangs- og endurvinnslurekstri þínum

Rusl- og endurvinnsluiðnaðurinn krefst endingargóða, skilvirkra og sjálfbærra lausna til að meðhöndla úrgang örugglega og lágmarka umhverfisáhrif. Saeplast-ílát eru hönnuð til að takast á við þessar áskoranir með því að bjóða upp á langvarandi, holla og hagkvæma lausnir fyrir úrgangsstjórnun, efnisendurvinnslu og meðhöndlun iðnaðarhliðarafurða.

1:

Auka endingu og draga úr kostnaði við endurnýjun

ÁSKORUN:

Hefðbundnar ruslatunnur og ílát brotna, springa eða versna fljótt, sem leiðir til títra skipta og hærri kostnaðar.

LAUSN:

Áhrifþolnir, þriggja veggja pólýetýlen-ílátar frá Saeplast endast 6–10 sinnum lengur en hefðbundnar lausnir, sem dregur úr endurnýjunartíðni og heildarkostnaði.

2:

Bætt hreinlæti og minnkun mengunar

ÁSKORUN:

Waste containers absorb liquids and odors, making cleaning difficult and increasing the risk of bacterial growth.

LAUSN:

Saumlausa, óporótta pólýetýlenhönnun Saeplast kemur í veg fyrir frásog, gerir kleift hraða og vandlega hreinsun og tryggir öruggari og heilbrigðari úrgangsmeðferð.

3:

Bætir skilvirkni geymslu og flutnings

ÁSKORUN:

Bulky, inefficient waste containers take up excessive space, increasing logistics and handling costs.

LAUSN:

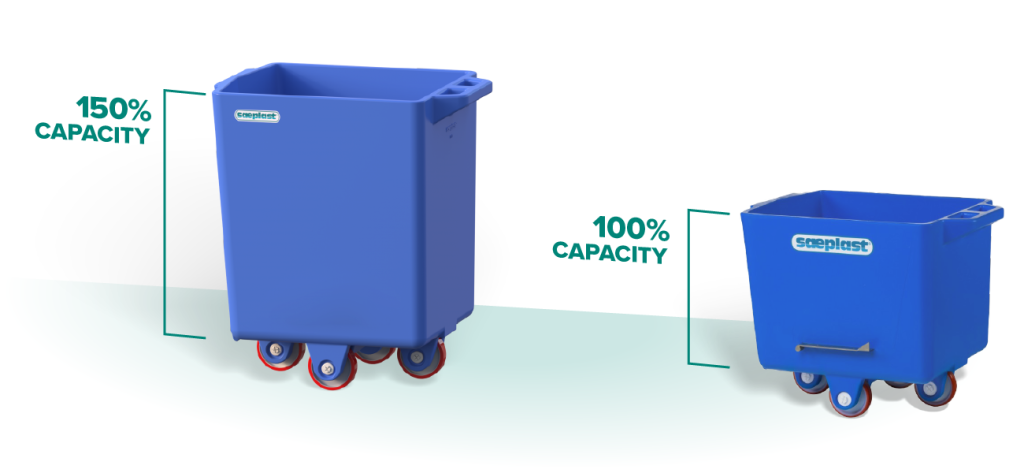

Stakkarhæfar og rýmissparandi hönnanir Saeplast hámarka geymslu og draga úr flutningskostnaði, sem gerir fyrirtækjum kleift að spara allt að 50–60% í tómflutningum.

4:

Að efla sjálfbærni með endurnýtanlegum og endurvinnanlegum efnum

ASKORUN:

Einnota eða óendurvinnanleg ruslahylki stuðla að mengun umhverfisins og háum förgunarkostnaði.

LAUSN:

Saeplast-ílát eru 100% endurvinnanleg, draga úr urðunarúrgangi og styðja aðgerðir í hringrásarhagkerfinu.

5:

Að draga úr laun- og viðhaldskostnaði

ASKORUN:

Ruslatunnur krefjast stöðugs viðhalds vegna brota, lekana eða rangrar meðferðar.

LAUSN:

Þolmiklar, gaffaltrukvænar tunnur frá Saeplast einfalda meðhöndlun, draga úr vinnufreku úrgangsstjórnun og viðhaldsþörf.

6:

Styðja hringrásarhagkerfi með lengri líftíma og viðgerðarþjónustu

ASKORUN:

Margir ruslatunnar hafa stutt líftíma, sem leiðir til of mikillar úrgangsmyndunar.

LAUSN:

Saeplast býður upp á viðgerðar- og leiguþjónustu sem lengir líftíma hvers gám og dregur úr úrgangi og kostnaði með tímanum.

Skuldbundin til sjálfbærni

í úrgangs- og endurvinnsluiðnaðinum

Hagkvæm sjálfbærni felur í sér meira en bara að vernda umhverfið – hún snýst um að bjóða upp á hagnýtar, kostnaðarhagkvæmar lausnir sem raunverulega skipta máli fyrir úrgangs- og endurvinnslustarfsemi. Endingargóðir, endurnýtanlegir pólýetýlen-ílátar okkar eru vandlega hannaðir til að lækka kostnað, auka skilvirkni og halda efnum í notkun lengur, sem styður við viðleitni þína til hringrásarhagkerfis og hreinni heims.

Ílát sem endast

Við smíðum ílátin okkar úr árekstrarþolnu, þriggja veggja pólýetýleni – sem gerir þau mun sterkari og endingargóðari en hefðbundin ílát. Aukin ending þeirra þýðir færri skiptingar, lægri kostnað og betri arðsemi.

Endurnýtanlegt að hönnun

Sæplast-ílát eru með ásetningi hönnuð til endurtekinnar notkunar, sem hjálpar starfsemi þinni að draga úr úrgangi og minnka kostnað sem tengist einnota- eða skammtímaúrræðum. Þau tákna snjallari, sjálfbærari langtímafjárfestingu.

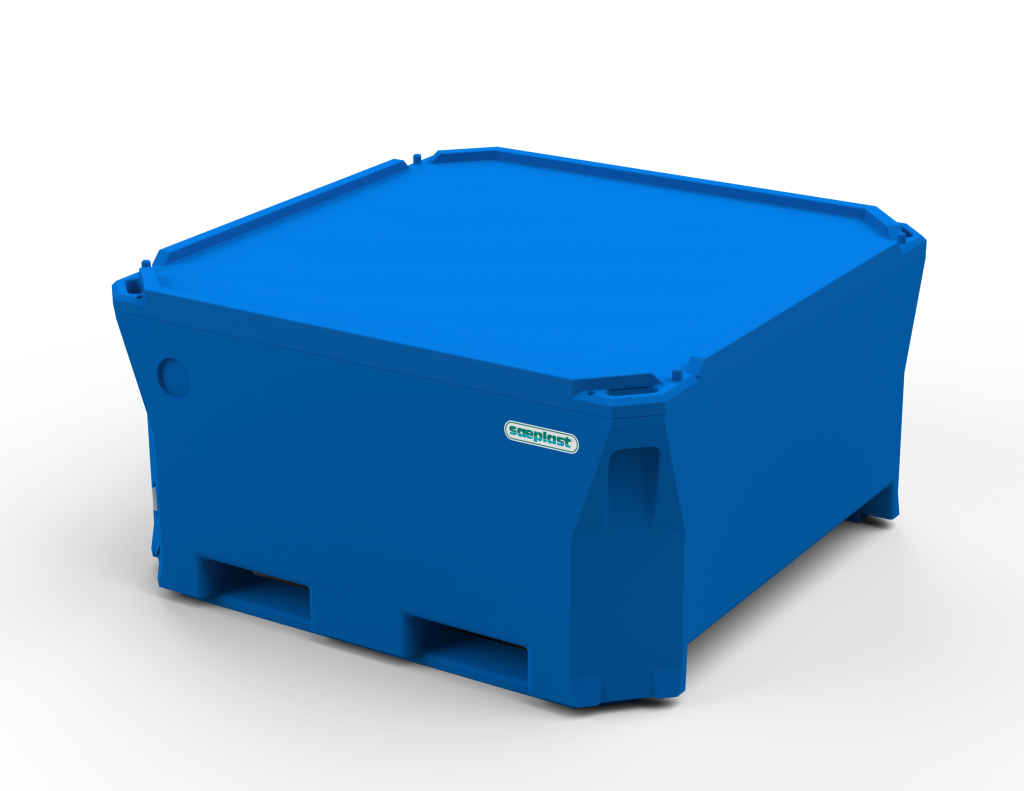

Rýmnisnýt samgöngur

Sæplast-ílátin eru með staflanlegri, rýmissparandi hönnun sem gerir kleift að hámarka flutninga og geymslu.

Auðvelt að þrífa og hreinlát

Sleipilausar, óporaríkar pólýetýlen-yfirborð okkar gera hreinsun hraðari, auðveldari og árangursríkari, sem sparar þér tíma, vatn og hreinsiefni. Minni fyrirhöfn, lægri kostnaður og aukin rekstrarhagkvæmni – allt í einu.

Stuðningur við markmið hringrásarhagkerfisins

Allir Sæplast-ílátar eru 100% endurvinnanlegir. Í lok nýtislífs síns er hægt að endurnýta þá að fullu, sem heldur verðmætum efnum frá urðunarstöðum og styrkir skuldbindingu þína gagnvart sjálfbærni og umhverfinu.

Sveigjanlegir viðgerðar- og leigumöguleikar

Til að hjálpa þér að fá sem mest út úr hverjum gám býður Sæplast einnig upp á viðgerðar- og leiguþjónustu. Þetta lengir líftíma vörunnar, dregur úr rekstrarkostnaði þínum og minnkar heildarumhverfisáhrif – sem gerir sjálfbærni bæði framkvæmanlega og hagnýta.

Komandi viðburðir

í úrgangs- og endurvinnsluiðnaðinum

There are no upcoming events.

Um vörurnar

Mótun iðnaðarins

iTUB: Sveigjanleg og sjálfbær leiga á kerum

Þegar sjávarafurðir eru landaðar skiptir hver mínúta máli. Hvernig þær eru meðhöndlaðar, geymdar og fluttar ræður því hversu mikill ferskleiki og verðmæti berast kaupandanum. Leiguþjónusta Sæplasts á iTUB veitir vinnsluaðilum og dreifingaraðilum betri leið til að stjórna flutningum sínum á sjávarafurðum. Í stað þess að binda fjármagn í búnað geta fyrirtæki leigt hágæða einangruð ker…

PE eða pappi? Skýrari sýn á réttu lausnina

Ef þú starfar í alifugla-, svínakjöts-, sjávar- eða rautt kjötsiðnaði, þá hefurðu líklega tekið eftir því að mikið af hráefnum þínum er geymt í svokölluðum bylgjupappa (þ.e. pappa). Hægt er að framleiða bylgjupappa kassa til að taka við magni hráefna ykkar til flutnings innan verksmiðjunnar. Það eru ástæður fyrir því að sumir kjósa þessa bylgjupappa…

B300 – Fyrir vinnslur sem gera kröfur

Eftir að hafa rætt við nokkra aðila í greininni komumst við að því að þörf væri á nýrri vöru sem gæti tekist á við meiri vinnslu hráefna. Sæplast tók þessa hugmynd og innleiddi hana í núverandi vörulínu okkar. Við höfum hannað þolmsterkasta, léttasta, þögulasta og starfsfólki vinalegasta PE-vagnana fyrir vinnslugólfið þitt.

Betra flæði og meiri stjórn í kjötvinnslu með Sæplast

Saeplast Americas Inc. er stolt af að kynna nýja vörulínu sína, Saeplast PE DMPC1450 kjötstangainnihaldshólfið, fyrir allar lausnir ykkar í matvælaframleiðslu. Þetta hólf er hannað til að bjóða upp á örugga og skilvirka lausn til meðhöndlunar stórra, unninna kjötstanga, sem gerir það að fullkomnum valkosti fyrir fyrirtæki í kjötiðnaðinum.

Aflinn skiptir máli. Meðhöndlunin líka!

Veiðar hafa verið mikilvægur uppspretta matar og tekna fyrir samfélög um allan heim í aldir. Hins vegar, þar sem eftirspurn eftir ferskum sjávarafurðum heldur áfram að aukast, hefur það orðið sífellt mikilvægara að tryggja að aflann sé meðhöndlaður rétt til að viðhalda gæðum og öryggi.

Minni úrgangur, meiri ábyrgð: Sjálfbær lausn frá Sæplast

Í heimi nútímans er sjálfbærni mikilvægur þáttur í öllum atvinnugreinum, og matvælaiðnaðurinn er engin undantekning. Fyrirtæki leita sífellt meira að umhverfisvænum valkostum sem draga úr úrgangi og lágmarka umhverfisáhrif sín.

Snjallari meðhöndlun um borð með lausnum frá Sæplast

Í annasömum heimi fiskveiðaiðnaðarins eru skilvirkni og öryggisstaðlar í fyrirrúmi. Þegar tækni þróast sífellt eykst einnig þörfin á nýstárlegum lausnum sem einfalda rekstur og tryggja velferð starfsmanna. Saeplast, brautryðjandi fyrirtæki í efnismeðhöndlun, er í fararbroddi með byltingarkenndum lausnum sem gjörbylta meðhöndlun um borð í fiskiskipum.

Hlutverk Sæplast í sjálfbærri fiskveiði

Í heimi þar sem umhverfisvernd er í fyrirrúmi leita iðnaðargreinar stöðugt leiðir til að starfa á sjálfbæran hátt. Fiskveiði- og sjávarútvegurinn stendur frammi fyrir sérstökum áskorunum við að samræma eftirspurn eftir sjávarfangi og þörfina á að varðveita vistkerfi hafsins.

Öruggari vinnsla með pólýetýlenkerum frá Sæplast

Í hraða heimi matvælaframleiðslu er afar mikilvægt að tryggja öryggi bæði starfsmanna og matvæla sem þeir meðhöndla. Einn oft vanmetinn en mikilvægt þáttur í þessu öryggi er val á meðhöndlunar- og flutningstækjum á vinnustaðnum.