Revolutionizing Seafood Logistics with Saeplast Twin Containers

Revolutionizing Seafood Logistics with Saeplast Twin Containers

Saeplast’s patented Twin Containers are a game-changer in seafood logistics, designed to cut transport costs, enhance storage efficiency, and maintain product quality. This innovative solution ensures reduced greenhouse effects, improved stacking security, and long-term sustainability.

Key Safety Considerations:

Space-Saving Design

The MS200 buggy features an ergonomic handle that reduces strain on the back and shoulders, making it easier and safer for workers to maneuver heavy loads.The polyurethane coated wheels add to better ergonomic use in that they are much easier to move when full as the force required is much less than steel buggy options.

Cost Savings in Transport & Handling

The amount of added noise pollution that is harmful to human hearing is reduced by using Saeplast PE Buggies and Containers. The design of the Saeplast product using polyurethane wheels on buggies and wear pads on the bottom of containers ensure excess noise is kept to a minimum as compared to steel option or wooden pallets.

Quality Preservation for Seafood

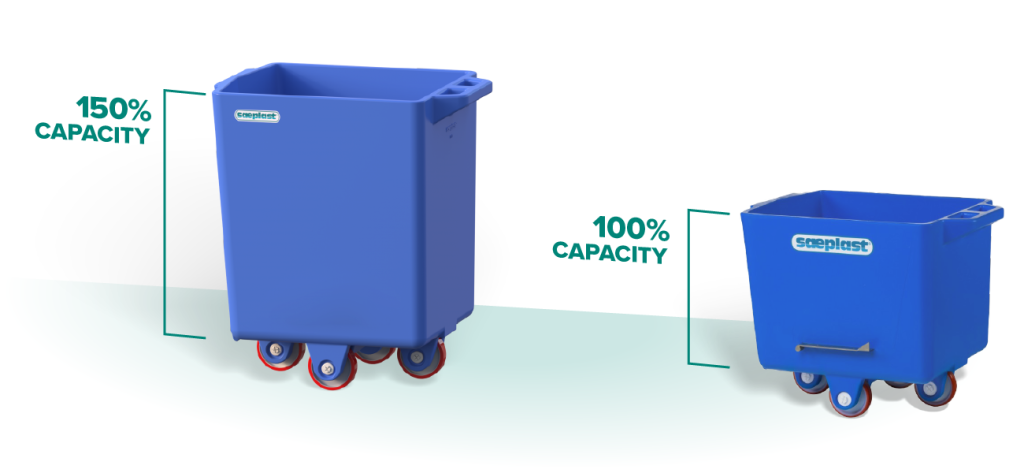

Sæplast’s PE boxes come in different heights, allowing for flexibility and reducing the need for awkward lifting and bending. The different height correlates to the volume that each container can hold thus allowing for control of batch volume.

Sustainability at the Core

The smooth interior and exterior walls and the overall rounded corner design of Sæplast boxes ensure that there are no sharp edges, minimizing the risk of cuts and abrasions, unlike cardboard, steel or injection molded plastic containers.

Advanced Cooling & Transportation Efficiency

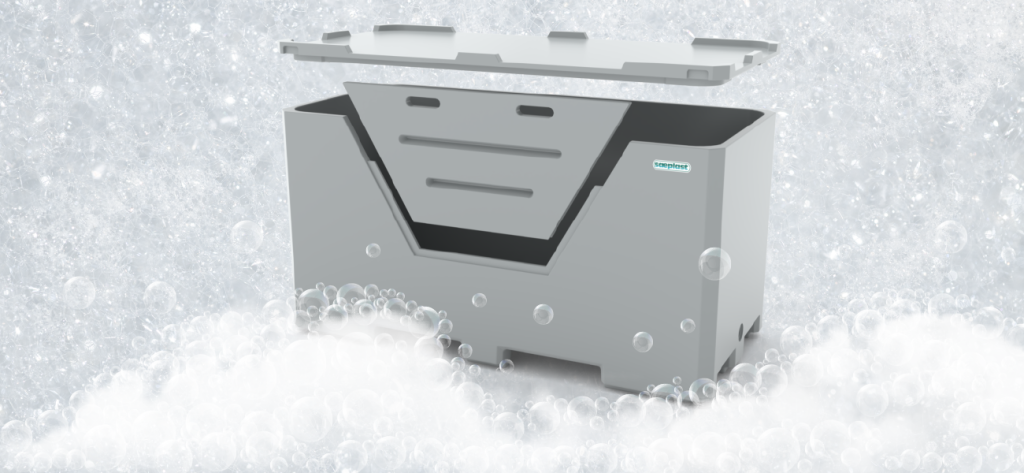

Optimized for Freshness – The containers support slurry ice transport, enhancing cooling efficiency and ensuring long-lasting freshness.

Lightweight & Compact – At 38 kg with a 290L capacity, each container holds 190-220 kg of salmon plus up to 50 kg of ice, offering the best balance of storage and transport efficiency.

Optimized Truckloads – Twin Containers reduce fuel usage and transportation weight, cutting costs and environmental impact.

Real-World Benefits: Proven Efficiency & Sustainability

Up to 25-50% savings in packaging and transport costs.

80% reduction in CO₂ emissions compared to traditional packaging methods.

53% improved utilization in empty return freight, reducing overall transport expenses.

Real-World Benefits: Proven Efficiency & Sustainability

Up to 25-50% savings in packaging and transport costs.

80% reduction in CO₂ emissions compared to traditional packaging methods.

53% improved utilization in empty return freight, reducing overall transport expenses.

The University of Iceland, published in Journal of Cleaner Production in January 2024. Environmental Impacts of Single-Use and Multi-Use Packaging for Fresh Fish Export

This study underscores the importance of transitioning from single-use to multi-use systems in reducing environmental impacts while maintaining cost and operational efficiency for fresh fish transport.

Read more about the report on our iTUB website: https://itub-rental.com/lca-report/

Saeplast Twin Containers: The Future of Seafood Logistics

By choosing Saeplast Twin Containers, seafood processors and transporters can:

✔ Lower operational costs with space-saving, long-lasting containers.

✔ Reduce waste with 100% recyclable, reusable materials.

✔ Enhance seafood quality with optimized cooling and handling.

✔ Improve sustainability with eco-friendly solutions that cut CO₂ emissions.

Upgrade your seafood logistics today! Contact Saeplast to discover how Twin Containers can transform your operations for efficiency, cost savings, and sustainability.

More Like This:

Sæplast Americas Inc. – Comparing PE Containers vs. Cardboard

The Importance of Employee Safety in Meat & Poultry Processing Plants If you’re in the poultry, pork, seafood or red meat industries, then you’ve most likely noticed that a lot of your raw food materials are stored in something called „corrugated boxes“ (i.e.: Cardboard). Corrugated boxes can be made to accommodate the volume of your…

Introducing the MS300: The Next Generation of Food Safe Industrial Buggies

The Importance of Employee Safety in Meat & Poultry Processing Plants After speaking with some industry players, we discovered the need for a new product that would hold a higher capacity for processing raw products. Sæplast took that idea and worked it into our current product line. We have designed the most rugged, lightweight, silent…

Logged & Secured: A Smarter Meat Processing Solution with Saeplast’s Meat Log Container

The Importance of Employee Safety in Meat & Poultry Processing Plants Saeplast Americas Inc. is proud to announce the launch of its new product line, the Saeplast PE DMPC1450 meat log container, for all your food processing solutions. This container is designed to provide a safe and efficient option for handling large, processed meat logs,…