Discover Sæplast for

Meat & Poultry

Discover Sæplast Containers and Buggies that are

Made to Solve Your Problems

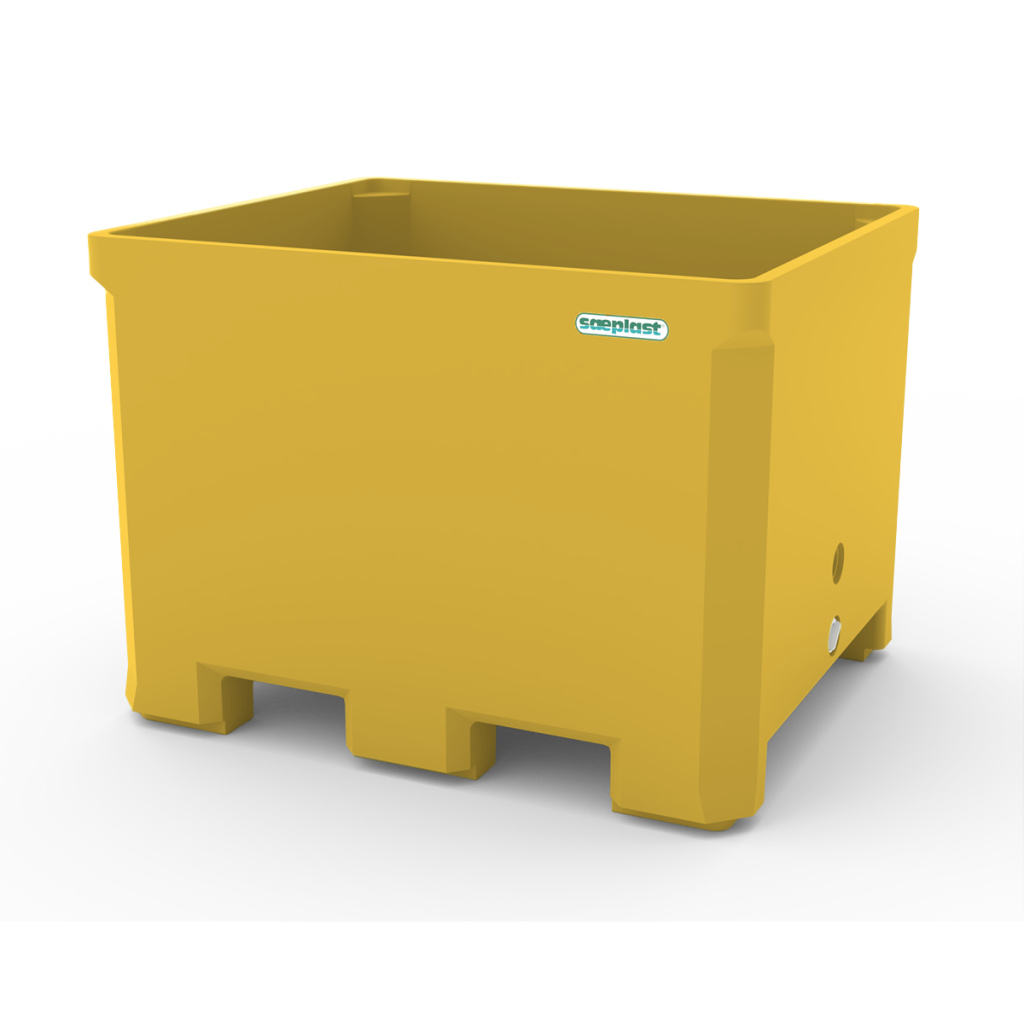

Built on decades of experience in demanding food sectors, Sæplast supports the meat and poultry industry with solutions that prioritize hygiene, handling efficiency, and food safety. From slaughterhouses to processing plants, our containers help streamline workflows, reduce contamination risks, and minimize product loss. Trusted by leading producers worldwide, we deliver reliability where it matters most.

By switching to Saeplast containers or buggies, meat and poultry processors can:

Ensure food safety and hygiene compliance

Reduce costs with long-lasting, impact-resistant materials

Improve efficiency in transport, storage, and handling

Enhance worker safety with ergonomic designs

Support sustainability with recyclable, reusable solutions

Shop All Meat & Poultry Products:

Why Use Sæplast

in Your Meat & Poultry Business

1:

Ensuring Superior Hygiene & Food Safety

CHALLENGE:

Bacteria growth and contamination risks from porous, hard-to-clean containers.

SOLUTION:

Saeplast containers and buggies are made from non-porous, seamless polyethylene, preventing liquid absorption and bacterial buildup. Their smooth surfaces allow for easy cleaning and sanitization, ensuring compliance with food safety regulations.

2:

Preventing Cross-Contamination

CHALLENGE:

Raw meat and poultry handling increase the risk of cross-contamination.

SOLUTION:

Color-coded Saeplast containers and buggies allow for segmented handling of different meats, reducing contamination risks and improving traceability and compliance in processing plants.

3:

Enhancing Durability & Reducing Replacement Costs

CHALLENGE:

Metal and single-wall plastic buggies dent, crack, and wear down quickly, leading to frequent replacements.

SOLUTION:

Sæplast’s impact-resistant, triple-wall polyethylene construction is engineered for significantly greater durability than standard plastic or metal alternatives—helping to reduce replacement frequency and lower total cost of ownership.

4:

Improving Worker Safety & Ergonomics

CHALLENGE:

Heavy, awkward buggies can lead to worker injuries and inefficiencies.

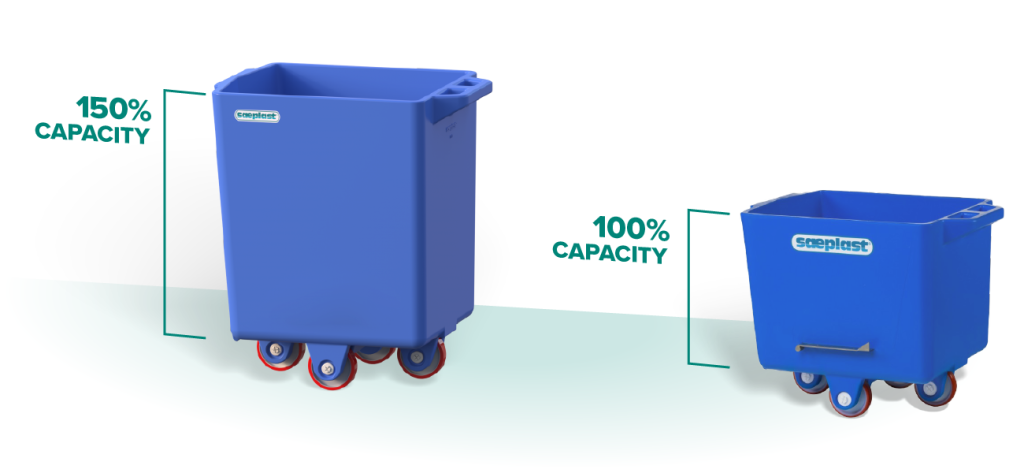

SOLUTION:

Saeplast buggies are designed with ergonomic features, smooth maneuverability, and forklift compatibility, reducing strain on workers and improving handling efficiency.

5:

Streamlining Transport & Storage Efficiency

CHALLENGE:

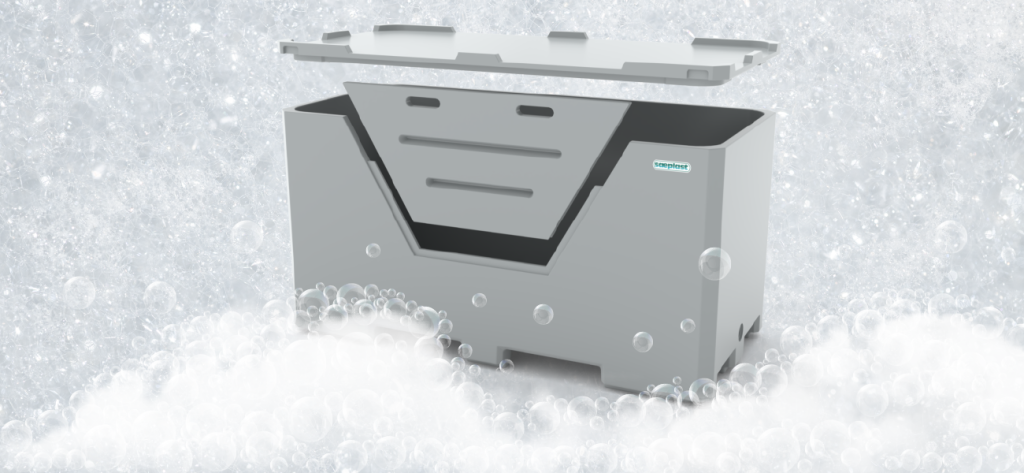

Inefficient stacking and poor space utilization lead to higher transport and storage costs.

SOLUTION:

Saeplast’s stackable, space-saving design allows for optimized storage and transport, reducing freight costs and improving facility organization.

6:

Supporting Sustainability & Cost Reduction

CHALLENGE:

Disposable or low-durability containers contribute to waste and high costs.

SOLUTION:

Saeplast’s reusable, 100% recyclable containers help reduce waste, carbon footprint, and long-term costs, making them a sustainable investment.

Best-in-Class Services:

Unique Advantages:

Committed to Sustainability

in the Meat & Poultry Industry

Sustainability is embedded in everything we design.

Our durable, reusable, and fully recyclable material handling solutions support the meat and poultry industry in reducing environmental impact, increasing operational efficiency, and maintaining the highest standards of food safety.

Durable, Long-Lasting Solutions

Sæplast containers and buggies are built with impact-resistant polyethylene and engineered for extended performance in demanding processing environments. Their longevity helps reduce waste and supports more cost-effective operations over time.

100% Recyclable Construction

Manufactured using monomaterial polyethylene, our containers are fully recyclable at the end of their service life. This supports circular economy initiatives by enabling responsible repurposing instead of disposal.

Hygienic and Easy to Clean

With seamless, non-porous surfaces, our containers are exceptionally easy to clean—minimizing water and chemical use while supporting strict hygiene protocols required in meat and poultry processing facilities.

Food Safety First

Our robust, hygienic designs help maintain clean handling environments, reducing the risk of contamination, spoilage, and product loss—ensuring consistent food safety from processing to distribution.

Repair and Rental Programs

To further extend product lifespan and minimize environmental impact, Sæplast offers repair and rental services—helping customers reduce capital expenditure while aligning with sustainability goals.

Upcoming Events

in the Meat & Poultry Industry

June 02 @ 10:00 am – June 04 @ 6:00 pm

VIV Europe 2026

About the Products

Moulding the Industry

Why Sæplast PE Buggies Deliver Long-Term ROI in Meat, Poultry, and Pet Food Processing

Operational Efficiency Is Not Optional in Protein Processing In meat, poultry, and pet food processing environments, operational efficiency is non-negotiable. Production floors operate under constant pressure, and when equipment fails or slows down, the consequences are immediate. Lost production time, increased labor costs, sanitation delays, and elevated food safety risk all compound quickly. One piece…

Agrosuper Chile: Improving Safety, Hygiene, and Operational Reliability with PE660 Containers

Supporting High Standards in Food Processing Agrosuper is one of Chile’s leading food producers, operating under some of the most rigorous food safety and hygiene standards in the region. At its Elaboradora de Alimentos Doñihue facility in Pudahuel, Metropolitan Region, these standards are enforced across every stage of sausage and processed meat production. In this…

iTUB Rental: Flexibility, Freshness, and Sustainability in the Saeplast Space

The Importance of Employee Safety in Meat & Poultry Processing Plants When seafood is landed, every minute matters. How it’s handled, stored, and transported determines how much freshness and value reaches the buyer. Sæplast’s iTUB Rental service gives processors and distributors a better way to manage their seafood logistics. Instead of tying up capital in…

Conxemar & Pollutec 2025

The Importance of Employee Safety in Meat & Poultry Processing Plants Sæplast is out in full force this week, exhibiting at two major trade fairs in Europe – Conxemar in Vigo, Spain (Stand 3C45) and Pollutec in Lyon, France (Hall 2 – Stand B104). Both exhibitions gather the people shaping the future of the seafood…

Sæplast Americas Inc. – Comparing PE Containers vs. Cardboard

The Importance of Employee Safety in Meat & Poultry Processing Plants If you’re in the poultry, pork, seafood or red meat industries, then you’ve most likely noticed that a lot of your raw food materials are stored in something called “corrugated boxes” (i.e.: Cardboard). Corrugated boxes can be made to accommodate the volume of your…

Introducing the MS300: The Next Generation of Food Safe Industrial Buggies

The Importance of Employee Safety in Meat & Poultry Processing Plants After speaking with some industry players, we discovered the need for a new product that would hold a higher capacity for processing raw products. Sæplast took that idea and worked it into our current product line. We have designed the most rugged, lightweight, silent…

Logged & Secured: A Smarter Meat Processing Solution with Saeplast’s Meat Log Container

The Importance of Employee Safety in Meat & Poultry Processing Plants Saeplast Americas Inc. is proud to announce the launch of its new product line, the Saeplast PE DMPC1450 meat log container, for all your food processing solutions. This container is designed to provide a safe and efficient option for handling large, processed meat logs,…

Maximizing the Catch: The Saeplast On-Board Handling Solution for Commercial Fishing

The Importance of Employee Safety in Meat & Poultry Processing Plants Fishing has been an important source of food and income for communities around the world for centuries. However, as the demand for fresh seafood continues to grow, it has become increasingly important to ensure that the catch is handled properly to maintain quality and…

Sustainable Solutions: How Saeplast Containers Reduce Environmental Impact in the Food Industry

The Importance of Employee Safety in Meat & Poultry Processing Plants Introduction In today’s world, sustainability is a critical aspect of any industry, and the food sector is no exception. Companies are increasingly seeking eco-friendly alternatives that reduce waste and minimize their environmental impact. Saeplast, a leader in the design and production of industrial containers,…

Revolutionizing Onboard Handling: Enhancing Efficiency and Safety in the Fishing Industry with Saeplast Solutions

The Importance of Employee Safety in Meat & Poultry Processing Plants In the bustling world of the fishing industry, efficiency and safety standards are paramount concerns. As technology continues to evolve, so does the need for innovative solutions that streamline operations and safeguard the well-being of workers. Saeplast, a trailblazing company in the material handling…