Uppgötvaðu Sæplast fyrir

Matvælavinnslu

Kynntu þér Sæplast:

Gerð til að endast og skila árangri

Sæplast býr yfir áratuga reynslu af því að styðja við krefjandi umhverfi í matvælavinnslu. Lausnir okkar eru hannaðar til að uppfylla ströng hreinlætisviðmið, bæta meðhöndlun efna og draga úr úrgangi í gegnum framleiðsluferlið. Frá meðhöndlun hráefna til fullunninna vara treysta leiðandi matvælavinnslufyrirtæki á okkur vegna öryggis, skilvirkni og langtímaendingu.

Með því að taka upp Sæplast-ílát og kerru geta matvælaframleiðendur:

Tryggja að farið sé eftir matvælaöryggis- og hreinlætisviðmiðum

Lægri rekstrarkostnað með endingargóðri og árekstrarþoltri byggingu

Bæta skilvirkni í meðhöndlun, geymslu og flutningsferlum

Styðjið sjálfbærnimarkmið með endurvinnanlegum og endurnýtanlegum lausnum

Fryrstu vinnuflæði og lækka launakostnað með vinnuaðlögun.

Verslaðu allar matvælavinnsluvörur:

Af hverju nota Sæplast

í matvælavinnslufyrirtækinu þínu

Matvælavinnslan stendur frammi fyrir ströngum kröfum um hreinlæti, skilvirkni og sjálfbærni. Saeplast-ílát og vagnar eru hönnuð til að takast á við þessar áskoranir, hjálpa vinnslufyrirtækjum að draga úr úrgangi, hámarka meðhöndlun og viðhalda matvælaöryggisstaðlum.

1:

Að tryggja framúrskarandi hreinlæti og fullnægju matvælaöryggisstaðla

ASKORUN:

Menguð eða porosityr ílát auka hættu á bakteríuvöxt og matarsýkingum.

LAUSN:

Saumlausir, óporaríkir pólýetýlen-ílátar frá Saeplast eru auðveldir í hreinsun, þola vel bakteríuvöxt og uppfylla að fullu reglugerðir um matvælaöryggi.

2:

Að koma í veg fyrir krossmengun

ÁSKORUN:

Meðhöndlun margra hrá- og unninna matvælaefna eykur mengunarhættu.

LAUSN:

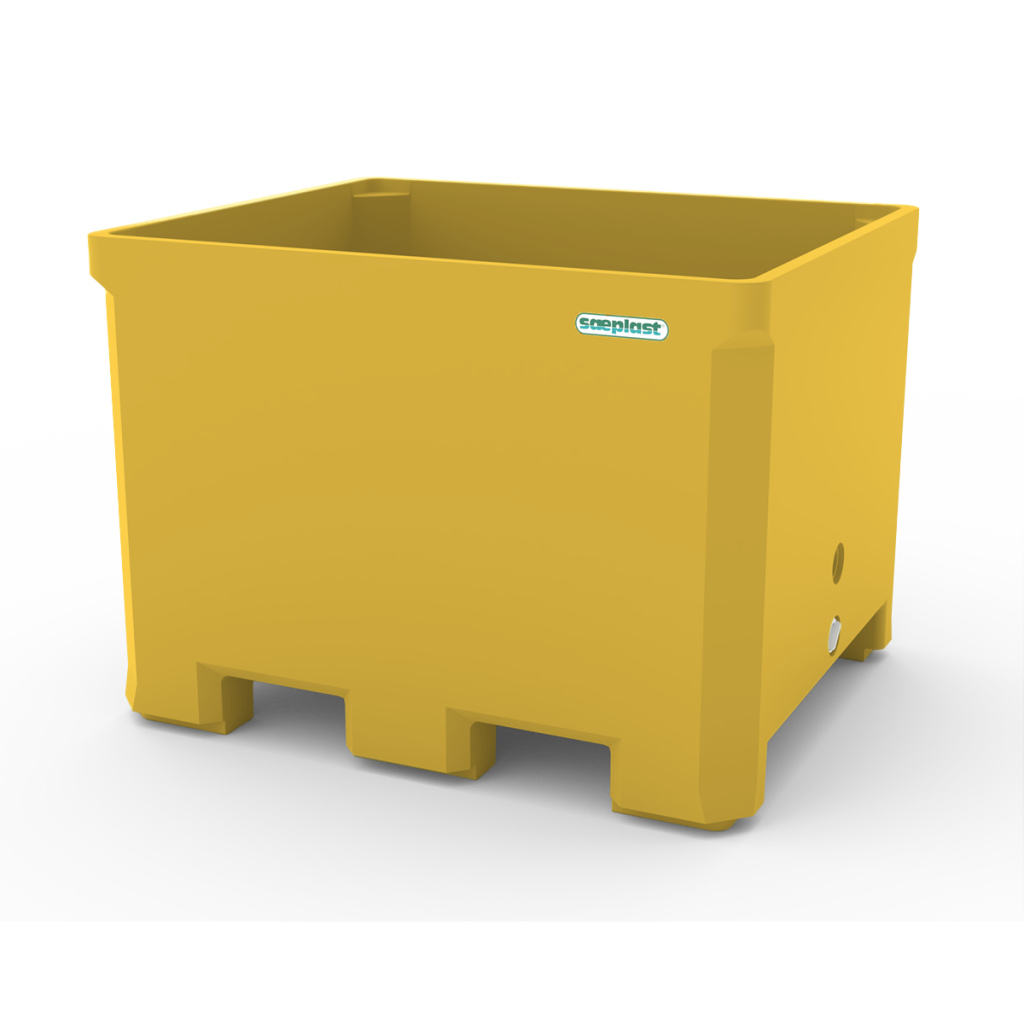

Color-coded Saeplast containers and buggies allow for segmented ingredient handling, reducing contamination risks and ensuring safe processing workflows.

3:

Að hraða hreinsunar- og sótthreinsunarferlum

ASKORUN:

Heavy, awkward containers slow down workflow and increase labor costs.

LAUSN:

Saeplast buggies and containers are designed for easy handling, forklift compatibility, and stackability, improving operational efficiency.

4:

Að bæta skilvirkni í meðhöndlun og flutningi

ASKORUN:

Þungir og klunnalegir ílátar hægja á vinnuflæði og auka launakostnað.

LAUSN:

Saeplast buggies and containers are designed for easy handling, forklift compatibility, and stackability, improving operational efficiency.

5:

Að viðhalda vörugæðum með hitastýringu

ASKORUN:

Varanleg hráefni krefjast nákvæmrar hitastjórnunar til að viðhalda ferskleika.

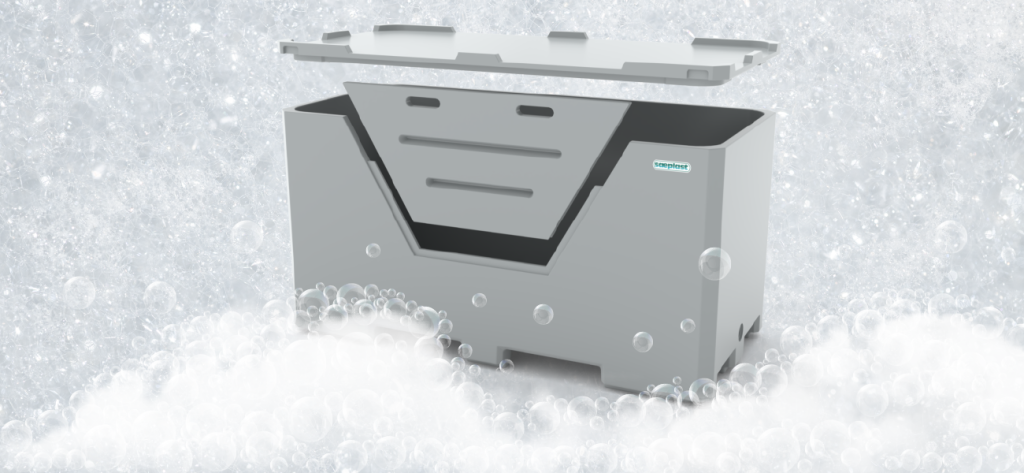

LAUSN:

Einangruð ílát frá Saeplast hjálpa til við að varðveita hitasækin efni, sem tryggir betri gæði matvæla og lengri geymsluþol.

6:

Að draga úr úrgangi og styðja sjálfbærnimarkmið

ASKORUN:

Einnota- eða skammtímaílát valda óþarfa úrgangi og háum kostnaði.

LAUSN:

Endurnýtanlegir og 100% endurvinnanlegir ílátar frá Saeplast stuðla að sjálfbærri matvælaframleiðslu með því að draga úr úrgangi, kolefnisspori og kostnaði.

Skuldbundin til sjálfbærni

in the Food Processing Industry

Ábyrg sjálfbærni nær lengra en að draga úr umhverfisáhrifum – hún táknar skuldbindingu okkar við að veita matvælavinnslufyrirtækjum endingargóðar, hagkvæmar og endurnýtanlegar lausnir. Með skuldbindingu okkar við endingargóð efni, hagræddar hönnanir og endurvinnsluhæfni gerum við matvælavinnslufyrirtækjum kleift að draga úr rekstrarkostnaði, lágmarka úrgang og auka skilvirkni – allt á sama tíma og uppfyllt eru hæstu matvælaöryggisstaðlar.

Kostnaðarsparnaður með endingargóðum og áreiðanlegum ílátum

Sæplast-ílát og kerrur, smíðuð úr árekstrarþolnu pólýetýleni, bjóða upp á lengri líftíma en hefðbundnar plast- og málmvörur. Þessi endingargeta dregur verulega úr úrgangi og kostnaði vegna endurnýjunar.

Endurnýtanleg hönnun sem dregur úr úrgangi

Ílátin okkar eru sérstaklega hönnuð fyrir endurtekna notkun, sem tryggir færri förgunartíðir og lægri heildarkostnað yfir líftíma. Þessi nálgun styður sjálfbæra starfsemi og verulega kostnaðarsparnað.

Bætt flutninga með staflanlegum, rúmsparandi gámum

Stakkarhæfar, plássparandi lausnir Sæplasts gera geymslu og flutninga skilvirkari.

Árangursrík hreinsun til að draga úr vatns- og efnanotkun

Með saumlausum, óporískum pólýetýlenyfirborðum gera Sæplast-ílát hreinsunarferla hraðari og árangursríkari. Þetta dregur úr vatnsnotkun og efnanotkun og lækkar beint kostnað matvælavinnslufyrirtækja.

Bætt matvælaöryggi og minnkuð vörutap

Hlutar okkar, sem eru hreinlætislegir og auðveldir í hreinsun, stuðla að því að tryggja bestu matvælaöryggisstaðla. Með því að koma í veg fyrir mengun og skemmdir draga þeir úr vörutapi, vernda heilleika vörunnar og auka heildaruppskeru.

Hringrásarhagkerfi með fullkomlega endurvinnanlegu efni

Gerðir alfarið úr endurvinnanlegu pólýetýleni styðja Sæplast-ílát hringhagkerfið. Í lok nýtingartíma þeirra er hægt að endurvinna þau í stað þess að henda þeim, sem dregur úr umhverfisáhrifum og förgunarkostnaði.

Alhliða viðgerða- og leiguþjónusta fyrir lengri líftíma

Til að auka sjálfbærni og kostnaðarhagkvæmni enn frekar býður Sæplast upp á viðgerðar- og leiguþjónustu. Þessar lausnir lengja líftíma íláta, lækka heildarrekstrarkostnað og draga verulega úr úrgangi.

Komandi viðburðir

í matvælavinnslu

Um vörurnar

Mótun iðnaðarins

iTUB: Sveigjanleg og sjálfbær leiga á kerum

Þegar sjávarafurðir eru landaðar skiptir hver mínúta máli. Hvernig þær eru meðhöndlaðar, geymdar og fluttar ræður því hversu mikill ferskleiki og verðmæti berast kaupandanum. Leiguþjónusta Sæplasts á iTUB veitir vinnsluaðilum og dreifingaraðilum betri leið til að stjórna flutningum sínum á sjávarafurðum. Í stað þess að binda fjármagn í búnað geta fyrirtæki leigt hágæða einangruð ker…

PE eða pappi? Skýrari sýn á réttu lausnina

Ef þú starfar í alifugla-, svínakjöts-, sjávar- eða rautt kjötsiðnaði, þá hefurðu líklega tekið eftir því að mikið af hráefnum þínum er geymt í svokölluðum bylgjupappa (þ.e. pappa). Hægt er að framleiða bylgjupappa kassa til að taka við magni hráefna ykkar til flutnings innan verksmiðjunnar. Það eru ástæður fyrir því að sumir kjósa þessa bylgjupappa…

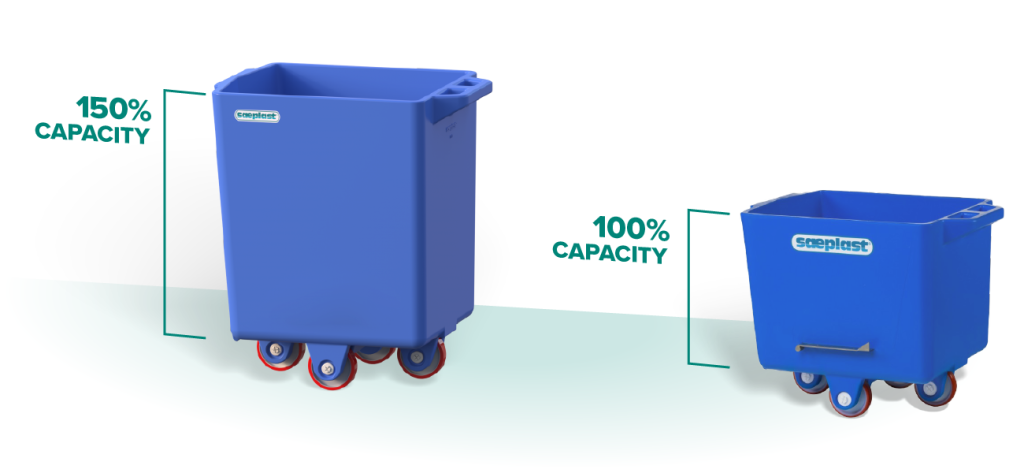

B300 – Fyrir vinnslur sem gera kröfur

Eftir að hafa rætt við nokkra aðila í greininni komumst við að því að þörf væri á nýrri vöru sem gæti tekist á við meiri vinnslu hráefna. Sæplast tók þessa hugmynd og innleiddi hana í núverandi vörulínu okkar. Við höfum hannað þolmsterkasta, léttasta, þögulasta og starfsfólki vinalegasta PE-vagnana fyrir vinnslugólfið þitt.

Betra flæði og meiri stjórn í kjötvinnslu með Sæplast

Saeplast Americas Inc. er stolt af að kynna nýja vörulínu sína, Saeplast PE DMPC1450 kjötstangainnihaldshólfið, fyrir allar lausnir ykkar í matvælaframleiðslu. Þetta hólf er hannað til að bjóða upp á örugga og skilvirka lausn til meðhöndlunar stórra, unninna kjötstanga, sem gerir það að fullkomnum valkosti fyrir fyrirtæki í kjötiðnaðinum.

Aflinn skiptir máli. Meðhöndlunin líka!

Veiðar hafa verið mikilvægur uppspretta matar og tekna fyrir samfélög um allan heim í aldir. Hins vegar, þar sem eftirspurn eftir ferskum sjávarafurðum heldur áfram að aukast, hefur það orðið sífellt mikilvægara að tryggja að aflann sé meðhöndlaður rétt til að viðhalda gæðum og öryggi.

Minni úrgangur, meiri ábyrgð: Sjálfbær lausn frá Sæplast

Í heimi nútímans er sjálfbærni mikilvægur þáttur í öllum atvinnugreinum, og matvælaiðnaðurinn er engin undantekning. Fyrirtæki leita sífellt meira að umhverfisvænum valkostum sem draga úr úrgangi og lágmarka umhverfisáhrif sín.

Snjallari meðhöndlun um borð með lausnum frá Sæplast

Í annasömum heimi fiskveiðaiðnaðarins eru skilvirkni og öryggisstaðlar í fyrirrúmi. Þegar tækni þróast sífellt eykst einnig þörfin á nýstárlegum lausnum sem einfalda rekstur og tryggja velferð starfsmanna. Saeplast, brautryðjandi fyrirtæki í efnismeðhöndlun, er í fararbroddi með byltingarkenndum lausnum sem gjörbylta meðhöndlun um borð í fiskiskipum.

Hlutverk Sæplast í sjálfbærri fiskveiði

Í heimi þar sem umhverfisvernd er í fyrirrúmi leita iðnaðargreinar stöðugt leiðir til að starfa á sjálfbæran hátt. Fiskveiði- og sjávarútvegurinn stendur frammi fyrir sérstökum áskorunum við að samræma eftirspurn eftir sjávarfangi og þörfina á að varðveita vistkerfi hafsins.

Öruggari vinnsla með pólýetýlenkerum frá Sæplast

Í hraða heimi matvælaframleiðslu er afar mikilvægt að tryggja öryggi bæði starfsmanna og matvæla sem þeir meðhöndla. Einn oft vanmetinn en mikilvægt þáttur í þessu öryggi er val á meðhöndlunar- og flutningstækjum á vinnustaðnum.