Why Saeplast Lids Are Essential for Container Performance

The lids of Saeplast containers are more than just covers—they’re an integral part of Saeplast’s innovative material handling solutions. From maintaining the cold chain to enhancing food safety and ensuring secure stacking, lids play a vital role in preserving product freshness and ensuring operational efficiency.

When it comes to maximizing the performance of Saeplast containers, the lid is a critical component. Here’s why:

Saeplast containers are frequently used to transport temperature-sensitive products like seafood, meat, pet food, and other proteins. Their lids ensure:

- Temperature Retention: By preventing cold air from escaping, lids maintain a stable internal environment.

- Ice Preservation: They reduce thawing, keeping products fresh for longer periods.

- Freshness Assurance: Lids help sustain optimal temperatures, preserving product quality and extending shelf life.

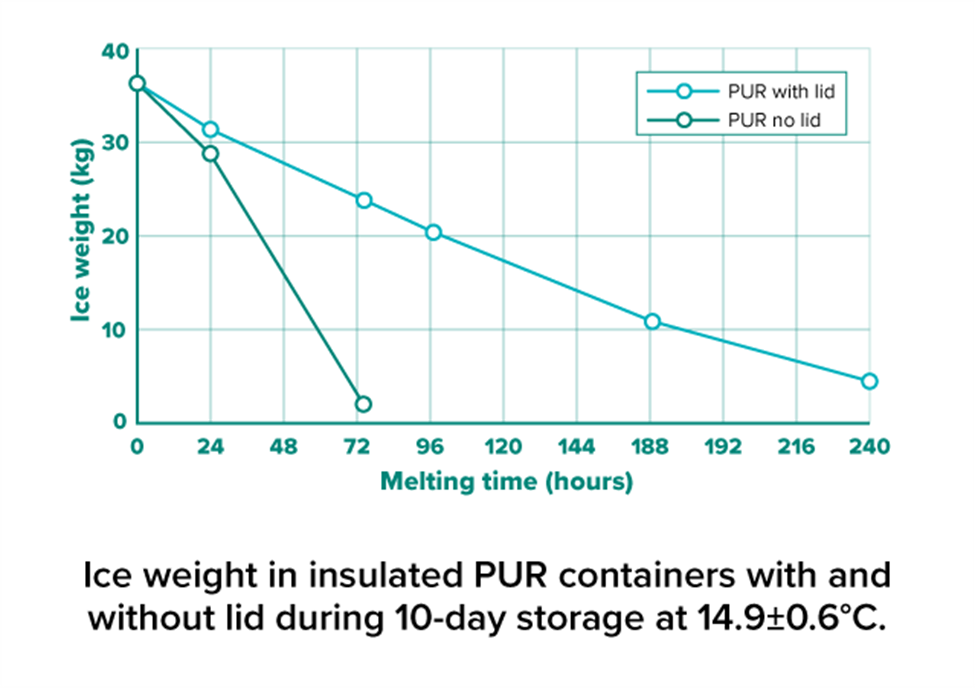

A study on Saeplast PUR containers revealed that containers without lids had only half the thermal retention (R-value) compared to those with lids. This highlights the critical role lids play in minimizing temperature fluctuations.

Adjustable Heights:

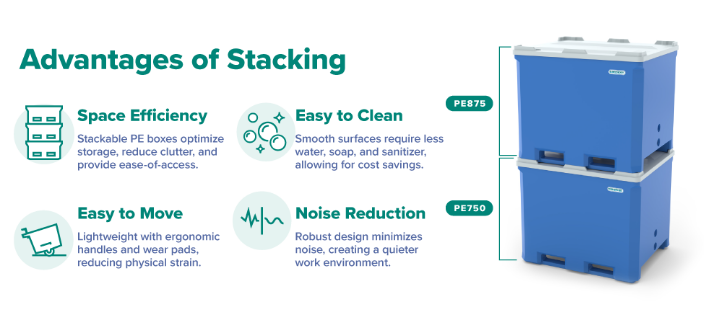

Stackable PE boxes optimize storage space, reducing clutter and making it easier to access materials without excessive reaching or bending.

Lightweight and equipped with ergonomic handles for buggies, and with wear pads on the bottom of boxes, Sæplast products are easy to move, reducing physical strain on workers.

Improved Efficiency:

Workers can perform tasks more efficiently and comfortably, leading to higher productivity and better overall performance.

Compliance and Reputation:

Using ergonomic solutions demonstrates a commitment to employee safety, helping to meet regulatory requirements and enhance the company’s reputation.

Cost Savings:

Utilizing a built to last reusable Saeplast buggy or container allows you to use the product day-after-day thus reducing your per-day cost for material handling products. As well, with the smooth wall design, savings can be achieved in the reduction of water, detergents, and sanitizers to clean the containers and buggies.

Ensuring employee safety in meat and poultry processing plants is vital for both worker well-being and operational efficiency. Sæplast’s ergonomic MS200 buggy and stackable PE boxes provide practical solutions to enhance safety and productivity. By investing in these items, companies can create a safer, more efficient, and compliant work environment.

Enhancing Food Safety

Food safety is paramount in industries like seafood, meat and poultry, pet food, and food processing. Saeplast lids significantly enhance food protection by:

- Preventing Contamination: Secure lids shield contents from external contaminants such as dust, water, and other particles.

- Ensuring Hygiene: They create a tight seal that minimizes exposure to harmful elements, safeguarding the contents’ integrity.

Supporting Circular Economy Goals

By reducing waste and preventing product damage during transport, Saeplast’s reusable lids align with sustainability initiatives:

- Durability: Designed for longevity, Saeplast lids reduce the need for single-use alternatives.

- Reusability: Together with containers, they help minimize waste and promote a circular economy.

Facilitating Safe Stacking and Transport

Saeplast lids are engineered with features that enhance safety and operational efficiency:

- Locking Mechanism: The container legs securely lock into the lid top, ensuring stability during stacking. This allows companies to optimize space in freezers and staging areas while maintaining safe operations.

Conclusion

Saeplast lids are far from being mere accessories; they’re essential components of the Saeplast container system. From preserving temperature and enhancing food safety to improving operational efficiency, these lids play a pivotal role in delivering excellence. Whether you’re transporting seafood, meat, or other perishables, a Saeplast container-lid system is an investment in quality and sustainability.

At Saeplast, we believe the lid is as valuable as the container in ensuring optimal performance and customer satisfaction.

More Like This:

Why Sæplast PE Buggies Deliver Long-Term ROI in Meat, Poultry, and Pet Food Processing

Operational Efficiency Is Not Optional in Protein Processing In meat, poultry, and pet food processing environments, operational efficiency is non-negotiable. Production floors operate under constant pressure, and when equipment fails or slows down, the consequences are immediate. Lost production time, increased labor costs, sanitation delays, and elevated food safety risk all compound quickly. One piece…

Agrosuper Chile: Improving Safety, Hygiene, and Operational Reliability with PE660 Containers

Supporting High Standards in Food Processing Agrosuper is one of Chile’s leading food producers, operating under some of the most rigorous food safety and hygiene standards in the region. At its Elaboradora de Alimentos Doñihue facility in Pudahuel, Metropolitan Region, these standards are enforced across every stage of sausage and processed meat production. In this…

iTUB Rental: Flexibility, Freshness, and Sustainability in the Saeplast Space

The Importance of Employee Safety in Meat & Poultry Processing Plants When seafood is landed, every minute matters. How it’s handled, stored, and transported determines how much freshness and value reaches the buyer. Sæplast’s iTUB Rental service gives processors and distributors a better way to manage their seafood logistics. Instead of tying up capital in…