Why Sæplast Containers Offer the Lowest Total Cost of Ownership!

Price vs. Cost: Understanding the Difference

Many businesses focus solely on the upfront price of material handling solutions, but the true cost lies in long-term durability, operational efficiency, and overall cost per use. A container that breaks easily, requires frequent replacement, or increases operational inefficiencies adds hidden expenses over time.

At Sæplast, we don’t just sell containers—we provide businesses with the most cost-effective and sustainable solutions. Instead of settling for cheaper, short-lived alternatives, investing in Sæplast means long-term savings and superior performance.

The Advantages of Sæplast PE: Eliminating Hidden Costs

When comparing containers, many options appear cost-effective at first but ultimately lead to higher expenses due to breakage, inefficiency, and safety risks.

Common Industry Challenges with Other Containers:

● One-time-use cardboard requires constant repurchasing and adds landfill waste.

● Fragile injection-molded plastics crack easily, leading to frequent replacements and sanitation issues.

● Single-wall bins lack stackability, increasing storage costs and inefficiency.

● Heavy steel bins are noisy, unsafe, and costly to repair.

Why Sæplast PE Outperforms Competitors

● 10-15 Year Lifespan – Reduces replacement costs.

● Superior Impact Resistance – Triple-wall construction withstands industrial wear and tear.

● Safer & Quieter Handling – Lightweight yet durable, reducing workplace injuries.

● Sustainable & Fully Recyclable – Supports circular economy initiatives.

Cost Efficiency:

A cheaper alternative may seem cost-effective, but the hidden costs of frequent replacements and inefficiencies quickly add up. Sæplast PE containers provide the lowest cost per day over their lifespan, making them the smarter financial investment.

Explore our Sæplast PE bins to see how they can benefit your operations.

The Advantages of Sæplast PUR: Built to Last 5-6 Times Longer

Not all insulated containers are created equal. Many competitors offer low-impact-resistant plastics that crack under pressure, fail in extreme temperatures, and require frequent replacements.

Common Industry Challenges with Other Insulated Bins:

● Standard insulated boxes are prone to cracking in cold storage.

● Low-impact plastics break easily under heavy loads.

● Short lifespan designs last only one to two years, leading to ongoing expenses.

Why Sæplast PUR Containers Last 5-6 Times Longer

● Unmatched Temperature Control – Maintains product integrity, preventing spoilage.

● Impact & Environment Resistant – Built for extreme conditions, including cold storage and rough transport.

● Optimized Storage & Handling – Stackable and easy to maneuver, reducing labor costs.

Cost Efficiency:

Unlike cheaper alternatives that need replacing every couple of years, Sæplast PUR containers last 5-6 times longer, resulting in lower total costs over time.

Learn more about our Sæplast PUR solutions to maximize your savings.

The Bottom Line: The Lowest Cost Per Day Wins

Businesses that focus on price alone often overlook the true cost of ownership. While a cheaper container may seem like a bargain, frequent breakage, operational inefficiencies, and safety risks lead to increased costs.

With Sæplast containers, you make an investment in durability, efficiency, and sustainability:

● Lower replacement costs

● Better workplace safety

● Reduced environmental impact

● Longer lifespan = lower cost per day

Looking for the best long-term investment?

Contact Sæplast today to discover how our containers can save your business money every single day.

Key Safety Considerations:

Ergonomic Design:

The MS200 buggy features an ergonomic handle that reduces strain on the back and shoulders, making it easier and safer for workers to maneuver heavy loads.The polyurethane coated wheels add to better ergonomic use in that they are much easier to move when full as the force required is much less than steel buggy options.

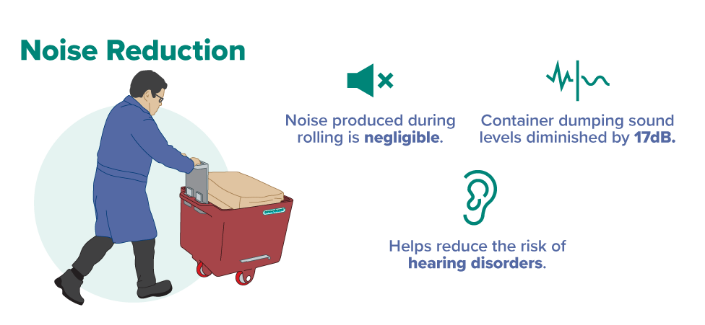

Noise Reduction:

The amount of added noise pollution that is harmful to human hearing is reduced by using Saeplast PE Buggies and Containers. The design of the Saeplast product using polyurethane wheels on buggies and wear pads on the bottom of containers ensure excess noise is kept to a minimum as compared to steel option or wooden pallets.

Adjustable Heights:

Sæplast’s PE boxes come in different heights, allowing for flexibility and reducing the need for awkward lifting and bending. The different height correlates to the volume that each container can hold thus allowing for control of batch volume.

Smooth Walls:

The smooth interior and exterior walls and the overall rounded corner design of Sæplast boxes ensure that there are no sharp edges, minimizing the risk of cuts and abrasions, unlike cardboard, steel or injection molded plastic containers.

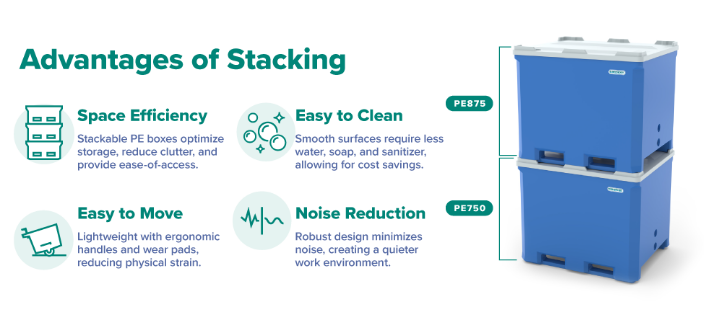

2. The Benefits of Stackable Sæplast Boxes

Sæplast boxes are designed to be stackable, offering several ergonomic and safety benefits. The ability of the base of one container to be securely held in place to the box below ensures a safe environment for employees not having to be concerned if the stack of boxes will topple over. Secondly, the interlinking of boxes allows for vertical storage up to 3-4 units high thus saving valuable floor space too.

Advantages of Stackable PE Boxes:

Space Efficiency:

Stackable PE boxes optimize storage space, reducing clutter and making it easier to access materials without excessive reaching or bending.

Easy to Clean:

The smooth surfaces of Sæplast boxes are easy to clean, ensuring a hygienic environment crucial in meat and poultry processing. With the smooth wall design of the interior and exterior of the box, less water, less soap, and less sanitizer are required in cleaning Saeplast PE Containers thus allowing you to realize a cost savings.

Easy to Move:

Lightweight and equipped with ergonomic handles for buggies, and with wear pads on the bottom of boxes, Sæplast products are easy to move, reducing physical strain on workers.

Noise Reduction:

The robust design of Sæplast boxes and buggies helps minimize noise levels in the processing plant, creating a quieter and more comfortable work environment.

3. Investing in Ergonomic Solutions

Investing in ergonomic equipment like the MS200 buggy and various PE boxes from Sæplast is essential for maintaining a safe and productive processing plant.

Reasons to Invest:

Reduced Injury Risk:

Ergonomic designs help prevent common workplace injuries, such as musculoskeletal disorders, by reducing physical strain.

Improved Efficiency:

Workers can perform tasks more efficiently and comfortably, leading to higher productivity and better overall performance.

Compliance and Reputation:

Using ergonomic solutions demonstrates a commitment to employee safety, helping to meet regulatory requirements and enhance the company’s reputation.

Cost Savings:

Utilizing a built to last reusable Saeplast buggy or container allows you to use the product day-after-day thus reducing your per-day cost for material handling products. As well, with the smooth wall design, savings can be achieved in the reduction of water, detergents, and sanitizers to clean the containers and buggies.

Ensuring employee safety in meat and poultry processing plants is vital for both worker well-being and operational efficiency. Sæplast’s ergonomic MS200 buggy and stackable PE boxes provide practical solutions to enhance safety and productivity. By investing in these items, companies can create a safer, more efficient, and compliant work environment.

More Like This:

Why Sæplast PE Buggies Deliver Long-Term ROI in Meat, Poultry, and Pet Food Processing

Operational Efficiency Is Not Optional in Protein Processing In meat, poultry, and pet food processing environments, operational efficiency is non-negotiable. Production floors operate under constant pressure, and when equipment fails or slows down, the consequences are immediate. Lost production time, increased labor costs, sanitation delays, and elevated food safety risk all compound quickly. One piece…

Agrosuper Chile: Improving Safety, Hygiene, and Operational Reliability with PE660 Containers

Supporting High Standards in Food Processing Agrosuper is one of Chile’s leading food producers, operating under some of the most rigorous food safety and hygiene standards in the region. At its Elaboradora de Alimentos Doñihue facility in Pudahuel, Metropolitan Region, these standards are enforced across every stage of sausage and processed meat production. In this…

iTUB Rental: Flexibility, Freshness, and Sustainability in the Saeplast Space

The Importance of Employee Safety in Meat & Poultry Processing Plants When seafood is landed, every minute matters. How it’s handled, stored, and transported determines how much freshness and value reaches the buyer. Sæplast’s iTUB Rental service gives processors and distributors a better way to manage their seafood logistics. Instead of tying up capital in…