Building Resilience and Sustainability in Shellfish Harvesting: The National Fish & Oyster Story

Building Resilience and Sustainability in Shellfish Harvesting: The National Fish & Oyster Story

Nestled in the pristine waters and fertile mudflats of Southern Puget Sound, National Fish & Oyster has been a trusted name in premium shellfish across the Pacific Northwest for nearly a century. This family-run business, spanning three generations, has consistently prioritized sustainability, freshness, and quality, establishing itself as a leader in the shellfish industry.

A Legacy of Commitment

Founded in 1929 by Samuel George Bulldis, National Fish & Oyster has grown and thrived under the stewardship of the Bulldis family. After Samuel’s passing in 1974, his sons George, John, and Jim continued his legacy, guiding the company through decades of growth and change. Now, with the third generation, led by Catherine Bulldis and her siblings, the company continues its dedication to innovation and environmental stewardship in the ever-evolving shellfish industry.

Facing Modern Challenges

As with many long-standing businesses, National Fish & Oyster faced operational challenges. For years, they used single-wall totes to transport shellfish, but these totes were prone to frequent breakage. This resulted in costly downtime, damaged shellfish, and production inefficiencies. Offloading from barges to the processing plant required significant labor, leading to higher mortality rates and inefficiencies in production.

Moreover, the lack of stackable design in these totes caused space constraints in the plant, limiting production capacity. Frequent tote breakage led to high replacement costs and operational disruptions, all of which impacted the quality and shelf life of the shellfish.

The Saeplast Solution

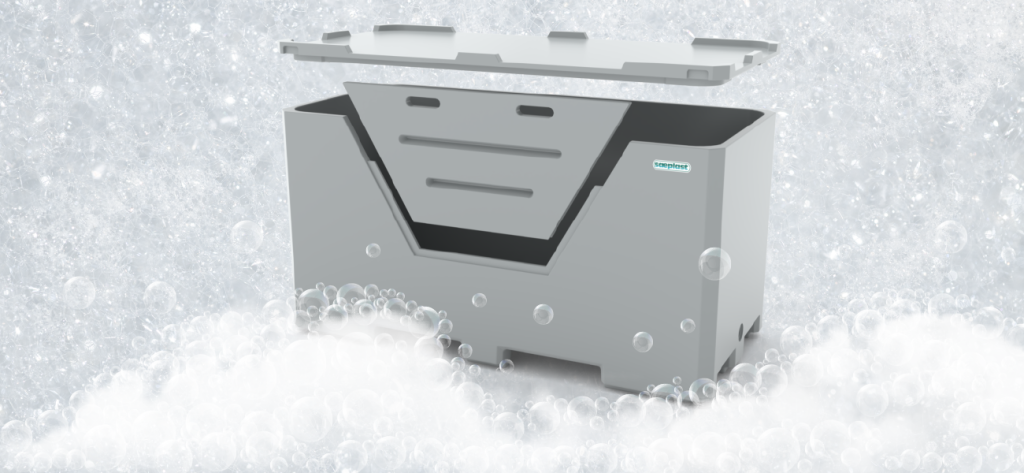

In search of a more durable and sustainable solution, National Fish & Oyster partnered with Saeplast. The introduction of the Saeplast MS 705 tote brought immediate benefits, addressing key operational challenges such as durability, space optimization, and employee safety.

Key Advantages of the MS 705 Tote

The Saeplast MS 705 tote revolutionized operations at National Fish & Oyster. Its robust design allows for secure stacking, optimizing storage space, and increasing production capacity. This stackability also improves the flushing process, ensuring the shellfish maintain peak freshness and longer shelf life, a key advantage in preserving the oysters' and geoducks' flavor and quality for extended periods.

In addition to these benefits, the totes offer operational flexibility. National Fish & Oyster can easily scale production to match seasonal demand by adjusting the number of totes in use. This ability to scale efficiently has been essential in maintaining profitability and meeting customer needs without compromising on quality.

Looking to the Future

With the recent acquisition of additional Saeplast totes, National Fish & Oyster is well-positioned for continued growth while upholding the highest standards of quality and sustainability. Employing a dedicated workforce and utilizing the durable Saeplast MS 705 totes, the company remains a leader in delivering fresh, high-quality shellfish to customers throughout the Pacific Northwest.

The partnership with Saeplast goes beyond logistics; it’s a commitment to sustainability and environmental health. By investing in reusable, durable containers that reduce waste and enhance product quality, National Fish & Oyster is securing the future of shellfish harvesting for generations to come.

More Like This:

Sæplast Americas Inc. – Comparing PE Containers vs. Cardboard

The Importance of Employee Safety in Meat & Poultry Processing Plants If you’re in the poultry, pork, seafood or red meat industries, then you’ve most likely noticed that a lot of your raw food materials are stored in something called „corrugated boxes“ (i.e.: Cardboard). Corrugated boxes can be made to accommodate the volume of your…

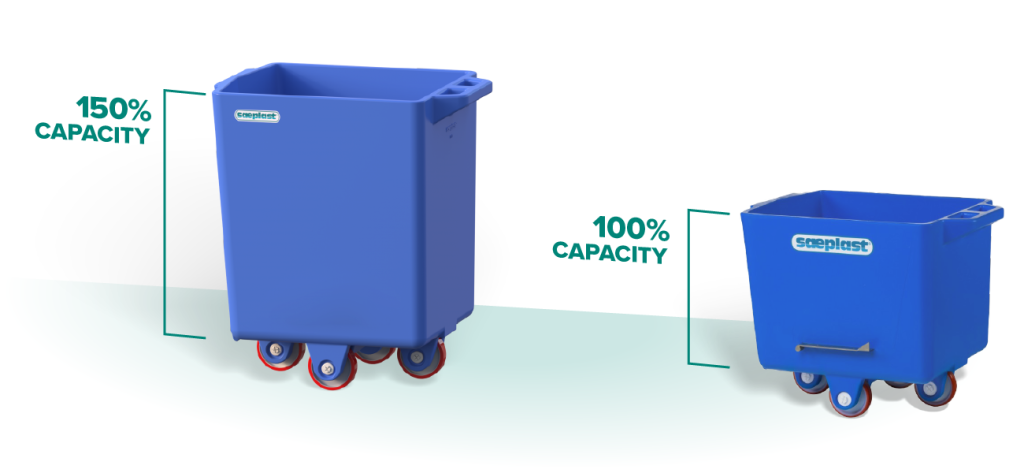

Introducing the MS300: The Next Generation of Food Safe Industrial Buggies

The Importance of Employee Safety in Meat & Poultry Processing Plants After speaking with some industry players, we discovered the need for a new product that would hold a higher capacity for processing raw products. Sæplast took that idea and worked it into our current product line. We have designed the most rugged, lightweight, silent…

Logged & Secured: A Smarter Meat Processing Solution with Saeplast’s Meat Log Container

The Importance of Employee Safety in Meat & Poultry Processing Plants Saeplast Americas Inc. is proud to announce the launch of its new product line, the Saeplast PE DMPC1450 meat log container, for all your food processing solutions. This container is designed to provide a safe and efficient option for handling large, processed meat logs,…