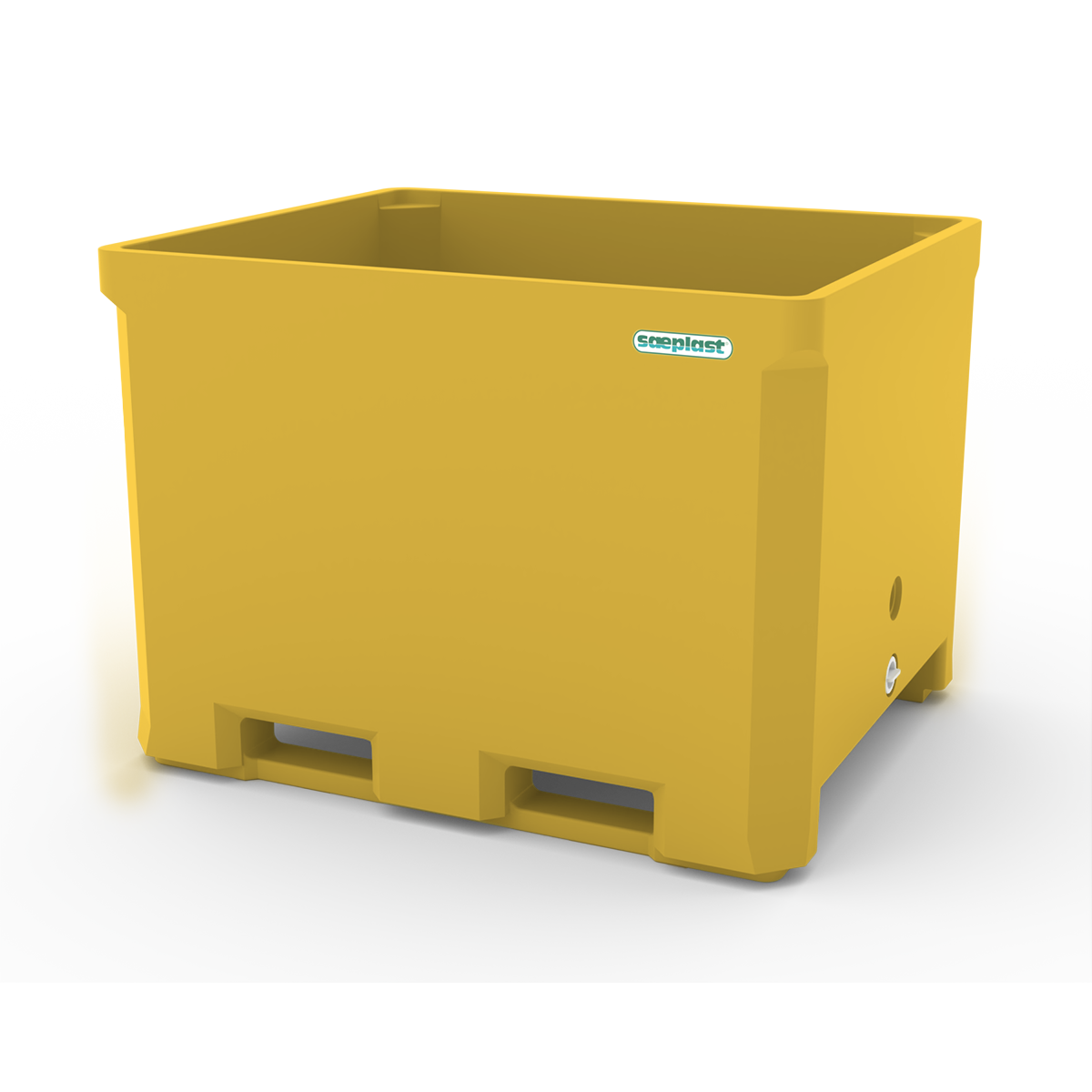

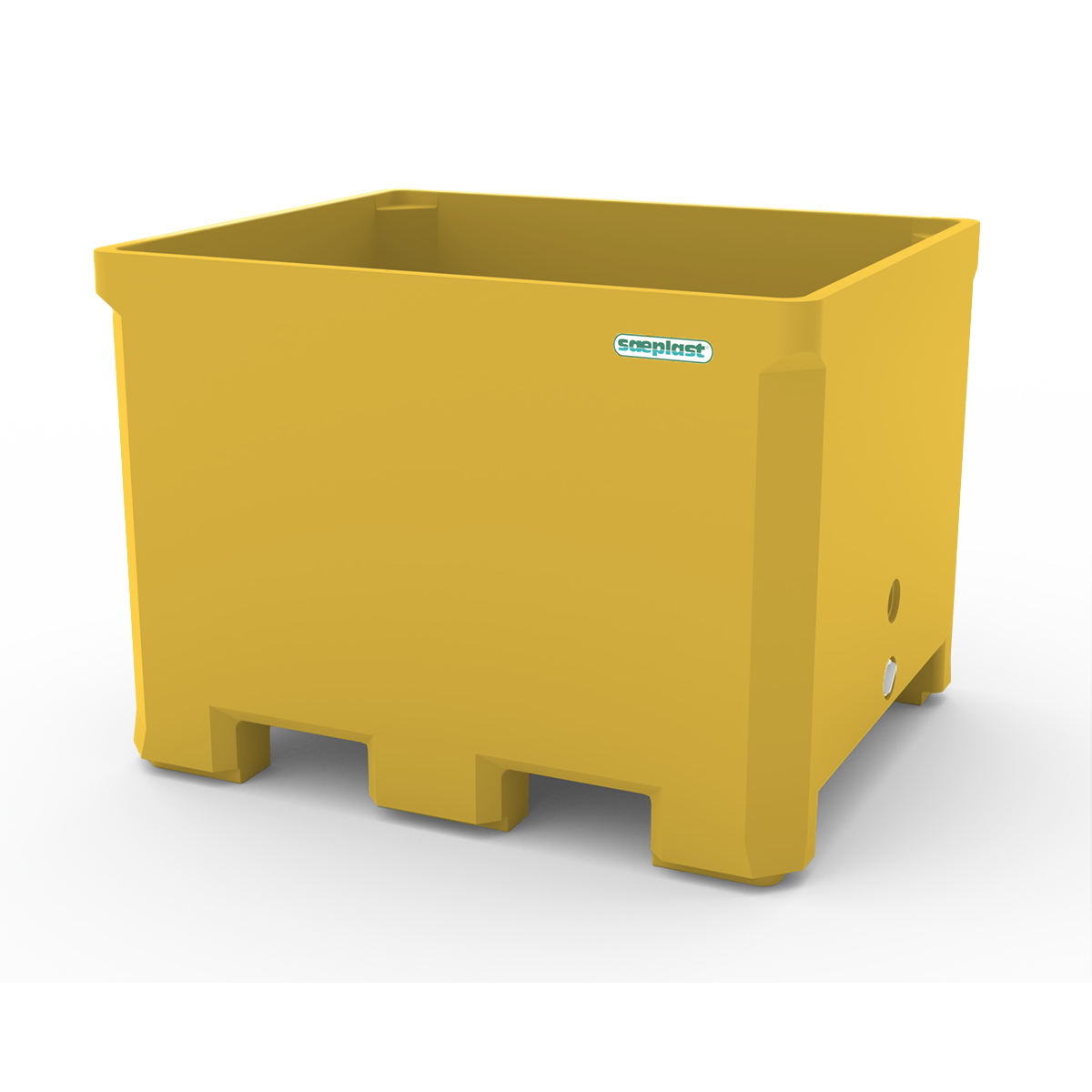

Sæplast B300 Buggy

B300 PE Buggy – NO LIFTING BRACKETS – no drain

Description

To maximize the value of your finished goods you need to ensure that your food products are fresh and safe. Sæplast has designed the most rugged, food safe, lightweight, silent and employee-friendly plastic buggy for your processing floor.

The Sæplast PE B300 PE Buggy is built to withstand the harsh conditions and rough handling in all processing plants. The robust B300 Buggy features a proven triple-wall polyethylene construction. The sturdy under-carriage has hard-wearing nylon wheels with polyurethane tread. These features all assist to benefit the safety of all workers.

The triple-wall polyethylene B300 PE buggy will absorb noise whereas its counterpart in stainless steel creates the usual noise pollution. The sound level during dumping is diminished by 17 db. Even the noise produced during rolling is minimized.

With the capability of using different colors, plants can color code buggies to specific areas of the plant. Furthermore, with the use of the reusable polyethylene lid, product inside the MS301 buggy can be assured to be food safe.

The Sæplast PE B300 Buggy is ideally suited for the handling of wet and dry products with a working capacity of 291 L with the capability of holding 600 lbs. of product. The low weight allows for easy handling.

Logistics – Product Per Transport Type

The figures are based on a full loading. Keep in mind that minor variations can occur due to different stacking techniques.

| Type | Quantity |

| 20ft container | 66 |

| 40ft container | 132 |

| 40ft HC Container | 132 |

| 53ft NA Truck | 135 |

Additional information

| Weight | 67419994987 kg |

|---|---|

| Dimensions | 6741978579 × 674199179898 × 6741993989 cm |

| Colour |

Highlights

Sæplast MS300 Buggy Meat Cart Any questions?

- Long lasting and robust

- Multifunctional -very low weight of 22 kg

- Easy to handle and clean

- Multiple colors for color-coded zones

- Nylon wheels – stainless steel axles

Product Description

To maximize the value of your finished goods you need to ensure that your food products are fresh and safe. Sæplast has designed the most rugged, food safe, lightweight, silent and employee-friendly plastic buggy for your processing floor.

The Sæplast PE B300 PE Buggy is built to withstand the harsh conditions and rough handling in all processing plants. The robust B300 Buggy features a proven triple-wall polyethylene construction. The sturdy under-carriage has hard-wearing nylon wheels with polyurethane tread. These features all assist to benefit the safety of all workers.

The triple-wall polyethylene B300 PE buggy will absorb noise whereas its counterpart in stainless steel creates the usual noise pollution. The sound level during dumping is diminished by 17 db. Even the noise produced during rolling is minimized.

With the capability of using different colors, plants can color code buggies to specific areas of the plant. Furthermore, with the use of the reusable polyethylene lid, product inside the MS301 buggy can be assured to be food safe.

The Sæplast PE B300 Buggy is ideally suited for the handling of wet and dry products with a working capacity of 291 L with the capability of holding 600 lbs. of product. The low weight allows for easy handling.

Logistics – Product Per Transport Type

The figures are based on a full loading. Keep in mind that minor variations can occur due to different stacking techniques.

| Type | Quantity |

| 20ft container | 66 |

| 40ft container | 132 |

| 40ft HC Container | 132 |

| 53ft NA Truck | 135 |

Specialized Branding

Ensure Your Containers Stand Out

and Represent Your Company

A great way to further enhance your brand is to add some distinct differentiators to your Saeplast products. We can set your Saeplast products up with graphics, logos, and special markings in various ways.

Silk Screen Printing

Silk screen printing is a one-colour deep print marking molded into the tub so it is extremely durable and permanent. We at Saeplast add the customer name, logo, or their marking on each tub, making the container easily identifiable. Silk screen markings are available in single colour format and colours available are black, blue, red or white.

Engraved Markings

Engraved markings ensure individual container identification. Engraved markings are long-lasting and are etched into the outside skin of the container. Many customers choose to have serial numbers, company name, factory location or other information engraved onto their Saeplast tubs.

Mould-in graphics

Mould-in graphics are a visual way to identify customer property by using their company logo or by applying a specially required graphic. The technology can also be used for marketing purposes or to strengthen branding. Mould-in technology can also be used to present user guidelines or other messages that need to be presented for specific use of the product.

Sæplast Services

We offer more than just selling containers.

Sæplast offers a whole ecosystem of services to support our products and ensure we can continue to offer a premium, sustainable product to industries. Our services are the reason our containers make sense for your business for the duration of their lifespan.

Reviews

There are no reviews yet.