Discover Sæplast for the

Fish & Seafood Industry

Discover Sæplast Containers that are

Made to Solve Your Problems

Sæplast was founded in 1984 in Iceland — one of the world’s most demanding fishing nations. Shaped by decades of experience in the North Atlantic, we understand what the seafood industry truly needs: durability, hygiene, and reliability. From landing to processing, our solutions help protect product quality, reduce waste, and support safer, more efficient operations

By investing in Saeplast fish and seafood containers, processors, distributors, and fishermen can:

Ensure premium quality seafood for higher market value

Reduce product loss and waste

Lower operational and transport costs

Improve hygiene and compliance with food safety regulations

Shop All Fishing Industry Products:

Why Use Sæplast

in Your Fish & Seafood Business

1:

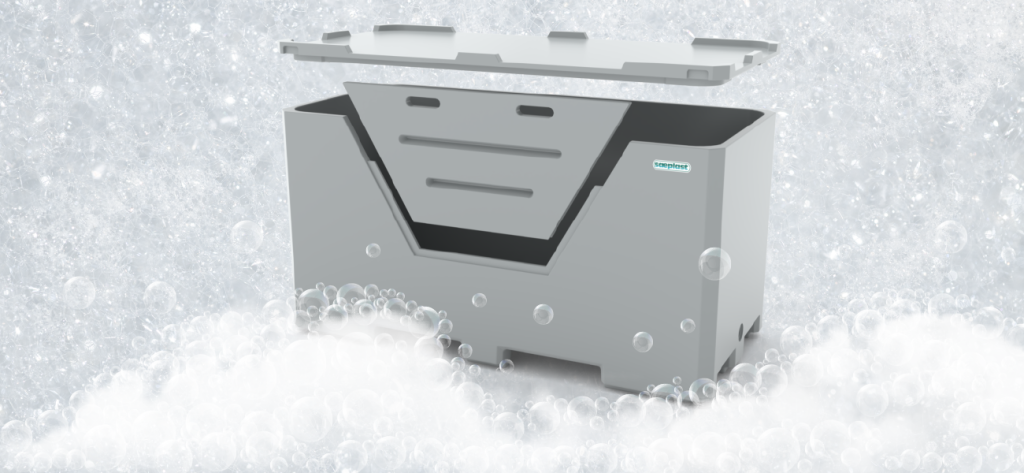

Maintaining Freshness & Extending Shelf Life

CHALLENGE:

Fish deteriorates quickly without proper temperature control.

SOLUTION:

Saeplast’s PE and PUR insulated containers maintain optimal temperatures, reducing ice melt and keep seafood fresher for longer.

2:

Reducing Handling Damage & Bruising

CHALLENGE:

Traditional single wall hand crates cause fish to bruise due to stacking pressure.

SOLUTION:

Saeplast containers minimize direct handling, protecting fish from damage and compression, ensuring higher-grade product quality.

3:

Enhancing Hygiene & Food Safety

CHALLENGE:

Bacteria growth and contamination risks from porous materials.

SOLUTION:

Saeplast containers are made from non-porous, easy-to-clean polyethylene, preventing bacterial buildup and cross-contamination.

4:

Improving Transport & Storage Efficiency

CHALLENGE:

Inefficient storage increases costs and logistical issues.

SOLUTION:

Saeplast’s stackable, nestable, space-saving containers optimize transport, reducing freight costs by up to 50-60% in backhaul transport.

5:

Supporting Sustainability & Cost Savings

CHALLENGE:

Single-use or low-durability containers create excessive waste and replacement costs.

SOLUTION:

Saeplast’s reusable, 100% recyclable containers offer long-lasting durability, lowering total cost of ownership and environmental impact.

6:

Optimizing Onboard & Processing Efficiency

CHALLENGE:

Slow offloading and inefficient workflow.

SOLUTION:

Saeplast’s ergonomic designs, forklift pockets, and drainage options enable faster, safer, and more efficient handling from vessel to plant.

Committed to Sustainability

in the Fish & Seafood Industry

Sustainability is integral to our approach to innovation.

Our durable, reusable, and fully recyclable containers are designed to support the fish and seafood industry in reducing environmental impact, improving operational efficiency, and maintaining product integrity throughout the value chain.

Built for Long-Term Use

Sæplast containers are constructed with robust triple-wall polyethylene, delivering exceptional durability in challenging seafood processing and logistics environments. Their long service life helps reduce waste and the frequency of replacements.

100% Recyclable Materials

Our containers are made from monomaterial polyethylene, allowing for full recyclability at end-of-life. This supports circular economy goals and helps prevent materials from ending up in landfills or marine ecosystems.

Transport Efficiency That Reduces Emissions

Innovative design features such as stackability and our Twin Container system allow for significantly more efficient backhaul transport. This contributes to lower freight emissions and reduced overall carbon footprint.

Superior Insulation for Ice Optimization

Engineered with effective thermal insulation, Sæplast containers help maintain consistent temperatures—minimizing ice melt, preserving seafood quality, and reducing energy use in the cold chain.

Designed for Hygiene and Food Safety

Seamless, non-porous polyethylene surfaces prevent moisture absorption and bacterial growth, supporting strict hygiene standards while extending product shelf life and reducing spoilage.

Lifecycle Services that Maximize Value

Through rental, repair, and refurbishment services, Sæplast enables customers to extend the life of each container—promoting more sustainable, cost-efficient operations across the seafood industry.

Upcoming Events

in the Fish & Seafood Industry

Stay in the Loop

Improving Fish Quality

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris ut blandit erat. Fusce efficitur non odio vitae fringilla. Integer lacus magna, pharetra vel sollicitudin porttitor, tincidunt quis leo. Donec sit amet tortor sagittis, tincidunt arcu a, rhoncus magna. Maecenas maximus dui in ex aliquam malesuada. Suspendisse vulputate vestibulum tortor. Pellentesque suscipit imperdiet nisl quis scelerisque.

Sæplast Americas Inc. – Comparing PE Containers vs. Cardboard

The Importance of Employee Safety in Meat & Poultry Processing Plants If you’re in the poultry, pork, seafood or red meat industries, then you’ve most likely noticed that a lot of your raw food materials are stored in something called “corrugated boxes” (i.e.: Cardboard). Corrugated boxes can be made to accommodate the volume of your…

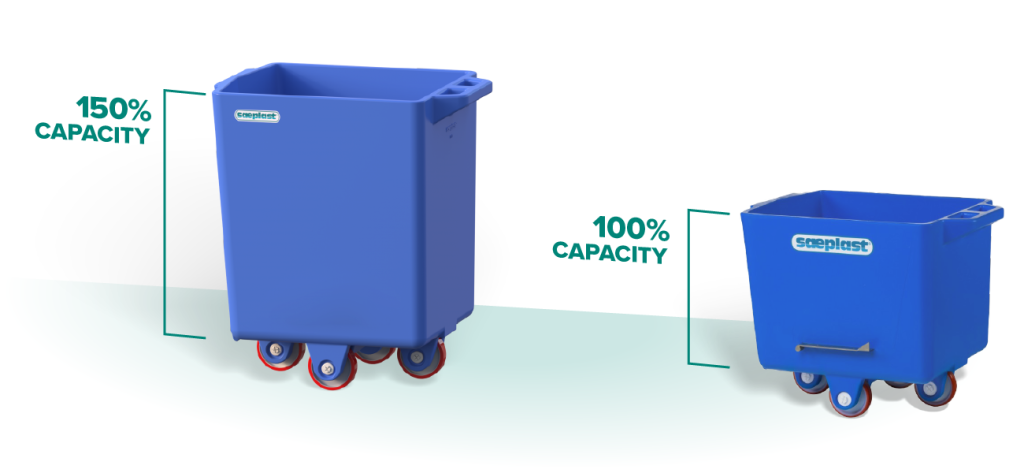

Introducing the MS300: The Next Generation of Food Safe Industrial Buggies

The Importance of Employee Safety in Meat & Poultry Processing Plants After speaking with some industry players, we discovered the need for a new product that would hold a higher capacity for processing raw products. Sæplast took that idea and worked it into our current product line. We have designed the most rugged, lightweight, silent…

Logged & Secured: A Smarter Meat Processing Solution with Saeplast’s Meat Log Container

The Importance of Employee Safety in Meat & Poultry Processing Plants Saeplast Americas Inc. is proud to announce the launch of its new product line, the Saeplast PE DMPC1450 meat log container, for all your food processing solutions. This container is designed to provide a safe and efficient option for handling large, processed meat logs,…

Maximizing the Catch: The Saeplast On-Board Handling Solution for Commercial Fishing

The Importance of Employee Safety in Meat & Poultry Processing Plants Fishing has been an important source of food and income for communities around the world for centuries. However, as the demand for fresh seafood continues to grow, it has become increasingly important to ensure that the catch is handled properly to maintain quality and…

Sustainable Solutions: How Saeplast Containers Reduce Environmental Impact in the Food Industry

The Importance of Employee Safety in Meat & Poultry Processing Plants Introduction In today’s world, sustainability is a critical aspect of any industry, and the food sector is no exception. Companies are increasingly seeking eco-friendly alternatives that reduce waste and minimize their environmental impact. Saeplast, a leader in the design and production of industrial containers,…

Revolutionizing Onboard Handling: Enhancing Efficiency and Safety in the Fishing Industry with Saeplast Solutions

The Importance of Employee Safety in Meat & Poultry Processing Plants In the bustling world of the fishing industry, efficiency and safety standards are paramount concerns. As technology continues to evolve, so does the need for innovative solutions that streamline operations and safeguard the well-being of workers. Saeplast, a trailblazing company in the material handling…

Saeplast’s Role in Sustainable Fisheries: Preserving Oceans for Future Generations

The Importance of Employee Safety in Meat & Poultry Processing Plants Introduction: In a world where environmental conservation is paramount, industries are continuously seeking ways to operate sustainably. The fishing industry, in particular, faces unique challenges in balancing the demand for seafood with the need to preserve marine ecosystems. Saeplast, a trailblazer in material handling…

The Significance of an Effective Repair Program: Fostering Sustainability with Saeplast

The Importance of Employee Safety in Meat & Poultry Processing Plants In the current global model where sustainable practices have become increasingly essential, the focus on implementing and maintaining effective repair programs has gained significant prominence. Saeplast, a leading figure in the industry, has recently introduced a comprehensive repair service for its robust containers, solidifying…

Enhancing Workplace Safety: The Role of Polyethylene Buggies in Promoting Employee and Food Safety

The Importance of Employee Safety in Meat & Poultry Processing Plants In the fast-paced world of food processing, ensuring the safety of both employees and the food products they handle is paramount. One often overlooked yet crucial aspect of this safety is the choice of handling equipment used within the workplace. Polyethylene buggies, also known as…

Using PE Containers Inside Fish Processing Plants: Why PE is a must!

The Importance of Employee Safety in Meat & Poultry Processing Plants Fish processing plants have one of the most complex food processes in the world. In order to stay ahead of the curve, it’s crucial for these plants to focus on efficiency and sustainability. You might be asking yourself what can be done to ensure…