Go Higher for Sustainability

Introduction

West Liberty Foods is a food manufacturer with a mission to convert needs, ideas, and expertise into value for its members, business partners, and consumers. As per their website, “West Liberty Foods means unwavering responsibility… To your brand, to your business, to our community, to the land and to our animals. It’s the guiding force behind everything we do.” Rooted in such core values as social responsibility, innovation and integrity,

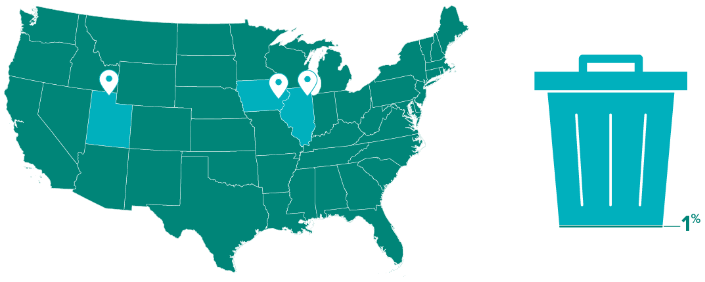

West Liberty Foods continues to lead in animal health and welfare, food safety, employee well-being, community impact and environmental stewardship. West Liberty Foods operates three facilities located in West Liberty, Iowa (head office location); Bolingbrook, Illinois; and Tremonton, Utah. In 2012, the company became a landfill-free company, and was independently verified by NSF International Strategic Registrations, demonstrating that less than 1% of all waste is being sent to a landfill. They are one of the first companies of their size in the United States to have this claim verified by a third-party organization. Since 2017 the company has diverted over 286,000 tons of waste from landfills.

Challenges with Plastic Injection Molded Containers & Pallets

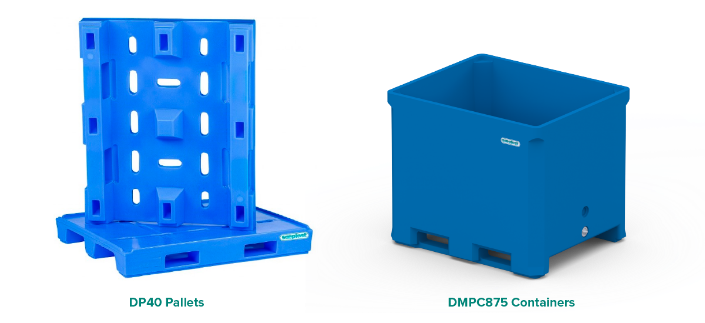

In 2010, West Liberty Foods converted to plastic-injection molded containers and pallets as part of its commitment to food safety. The company believed that pallets and containers made from polyethylene would mitigate the risk of bacteria cross contaminating their food products. However, the initial products proved to be brittle and difficult to sanitize, resulting in high costs due to their lack of durability. Every week, the company lost several pallets and bins to breakage, which increased its operational expenses.

Adoption of Saeplast Products

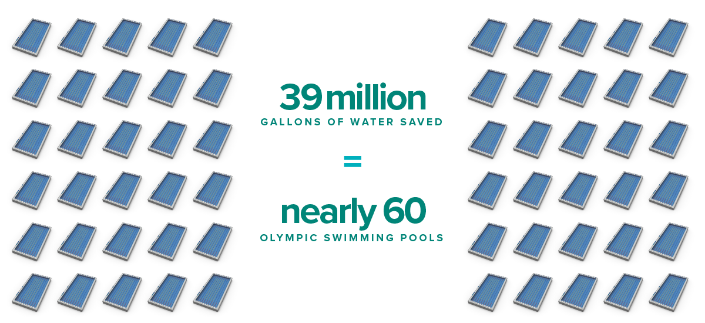

Mid-year 2012, West Liberty Foods converted to Saeplast rotationally molded DP40 pallets and triple-wall polyethylene DMPC875 containers, and both products have performed exceptionally well. The company broke a total of two pallets in over a year, after breaking hundreds per year of the injection-molded equivalent. Although the purchase price of these products is significantly higher than the initial plastic-injection molded containers and pallets, the total cost of acquisition is significantly lower than any other option West Liberty Foods has tried or analyzed. The same holds true for West Liberty Foods’ processing bins, as these DMPC875 model containers have proved to be superior in all aspects, including the amount of water and sanitizer required to clean and return them to the floor. The company is now analyzing other Saeplast products for the future, as these products have proven to be superior to anything West Liberty Foods has seen in the past.